by Nishimura Advanced Ceramics.

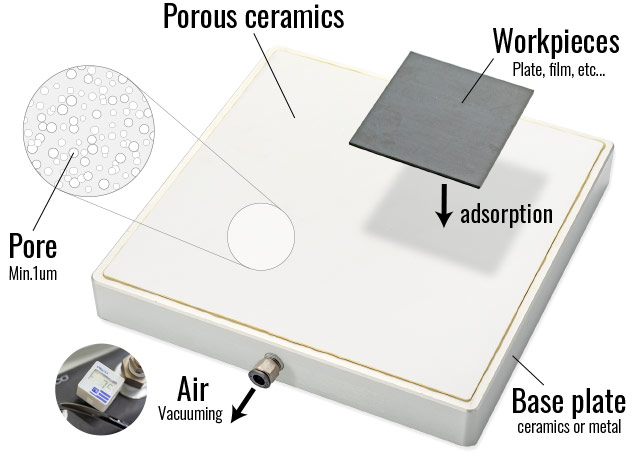

by Nishimura Advanced Ceramics.The ANYCHUCK is a ceramic vacuum chuck with ultra-fine pores of Φ1 µm minimum, enabling strong and safe vacuum fixation of even extremely small and ultra-thin workpieces. The chuck table, which enables partial suction, allows multiple workpieces of different shapes and sizes to be fixed simultaneously, reducing the time lost when changing vacuum chucks. Repeated operations such as machining, inspection and transport can be more efficient.

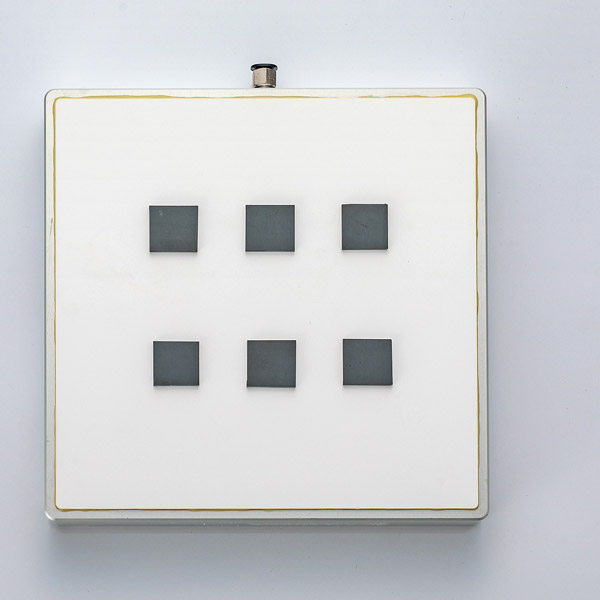

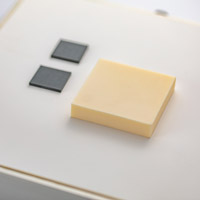

A single vacuum chuck can be used to simultaneously hold multiple extremely small workpieces, for example, for transporting multiple workpieces together, or for simultaneously holding and inspecting workpieces of different shapes. Conventional vacuum chucks are based on the principle of one chuck per workpiece, and air leaks occur unless the entire surface of the chuck is covered; with ANYCHUCK, multiple chucks can be placed on a single platform , and can be fixed freely in any position on the table. It can also be used for floating transport by pumping air.

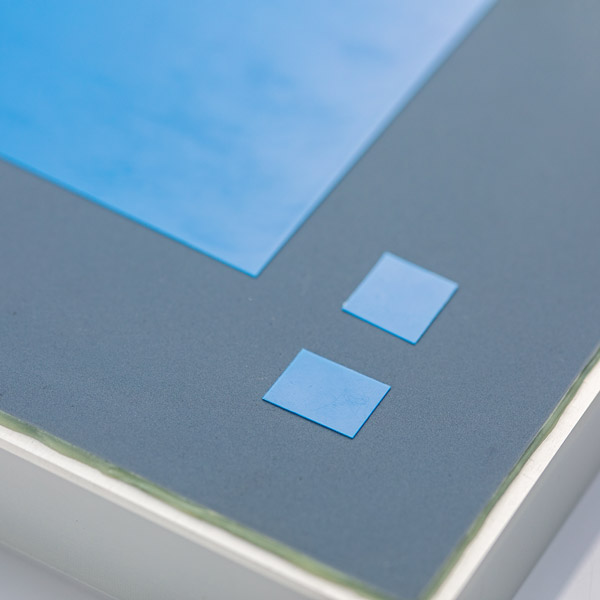

A single ANYCHUCK flexibly handles different sizes, fixing and working with thin workpieces of different diameters and shapes or sucking and polishing workpieces of different sizes. This eliminates the need to change the vacuum chuck to suit the workpiece size*. A wide range of workpiece materials can also be adsorbed, including substrates, ceramics, wafers, and films.

* The appropriate porous material may vary depending on the workpiece material. We will be pleased to suggest the most suitable material.

Partial adsorption performancePartial adsorption

Partial adsorption performancePartial adsorption

Air leaks occur if the entire surface of the vacuum chuck is not covered.

→Chuck needs to be replaced every time the workpiece size changes.

Partial suction vacuum chuck Any-Chuck does not cause air leakage

“Partial suction performance”

→One chuck can be used for different workpiece sizes.

Suitable for thin workpieces

Suitable for thin workpieces

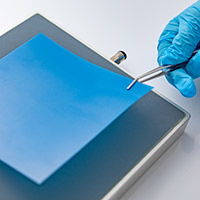

When working with thin workpieces such as film and metal foil, the chuck can safely suck and clamp the workpiece while correcting its warpage, and has a proven track record in handling ultra-thin workpieces down to a few microns. Three grades of vacuum chuck material are available, which can be selected to control the degree of warp correction or to provide anti-static measures, depending on the workpiece.

Conventional vacuum chucks have large pore diameters, causing deformation, distortion, scratches and other problems with ultra-thin workpieces such as film and metal foil, etc. ANYCHUCK’s pores are 1 µm to 5 µm in diameter and the almost smooth table surface protects the workpiece from trouble. The optimum pore diameter depends on the material of the workpiece, etc. We would be happy to test this on our demo kit. (Rental demo kit available)

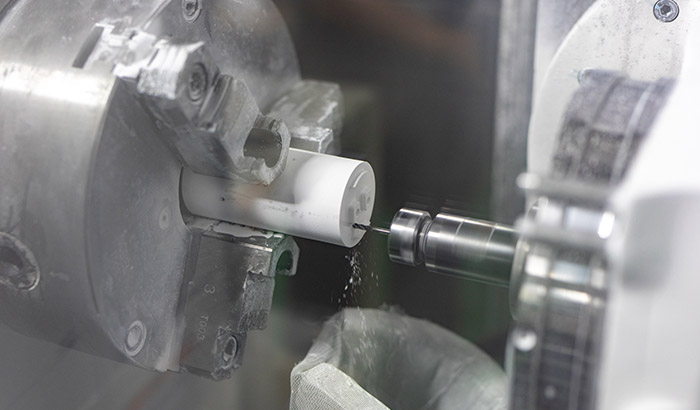

We can machine ceramic vacuum chucks to any size and shape. We can also supply base and vacuum chuck units designed to be mounted on machines, as well as porous plates that can be used simply by placing them on top of conventional vacuum chucks, in order to meet your needs.

We can provide products that meet your requirements in terms of the material of the base part, type of porous plate, etc. High-precision flat and parallel polishing is also available. (~1 µm flatness)

| Maximum production size | 2000mm×2000mm |

|---|---|

| Various types of machining work available | Machined to any shape/positioning holes Threaded holes in the base, etc. |

| Suitable environment | Dry/Wet environment High temperature environment up to 500°C (vacuum chuck only) |

| Adhesion strength | Sufficient to enable surface grinding of workpieces. |

| Material | Porous material: white material (1um), green to blue material Anti-static material Base plate material: Ceramic, Metal, or Granite |

| Form of supply | Unit type (base + porous plate) or Porous plate |

| Conventional Porous chuck (Before Anychuck) | ANYCHUCK | |

|---|---|---|

| Workpieces smaller than the porous surface | Not adsorbable | Adsorbable |

| Multiple adsorption | Only one workpiece at a time | Multiple workpieces can be adsorbed at once |

| As a Fixture | Design and production required on a case-by-case basis | Always good to go |

| Thin workpiece support | May cause Suction marks | Leaves no adsorption marks Semi-mirror to mirror polish possible. |

Nishimura Advanced Ceramics has a demonstration machine for the ANYCHUCK ceramic vacuum chuck. The most suitable product depends on the workpiece and workflow handled by the customer, so we would be delighted if you could contact us and carry out a practical test with a demonstration machine.

Click here for inquiries