Nishimura Advanced Ceramics has a history of over 100 years as a manufacturer of industrial ceramic materials, and even today we continue to accumulate experience and know-how through continuous trial and error. We are ready to help our customers solve their problems by utilizing our expertise in the development of various ceramic products as well as vacuum chucks.

Integrated productionIntegrated

Integrated productionIntegrated

We have an integrated manufacturing process from raw material preparation, molding, firing, processing, and inspection to the finished product. It allows us to flexibly respond to customer needs, applications, and issues. We also have in-house production facilities, so we can actively respond to small-lot production and prototyping.

Please feel free to tell us your issues and concerns. After hearing from you, we will discuss specifications, material selection, and design together.

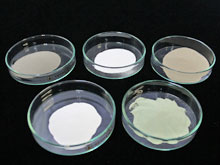

We offer optimal proposals from more than 100 types of raw materials, including alumina, zirconia, yttria, and aluminum nitride, and so on

We have our own machining process in our factory, which allows us to process the products into any shape. We can also accommodate detailed specifications, such as machining holes for workpiece positioning.

Grinding/lapping is performed in-house. Depending on the size, high-precision grinding at the 1um level of flatness is possible.

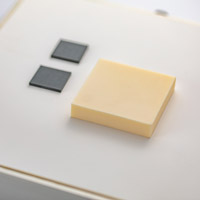

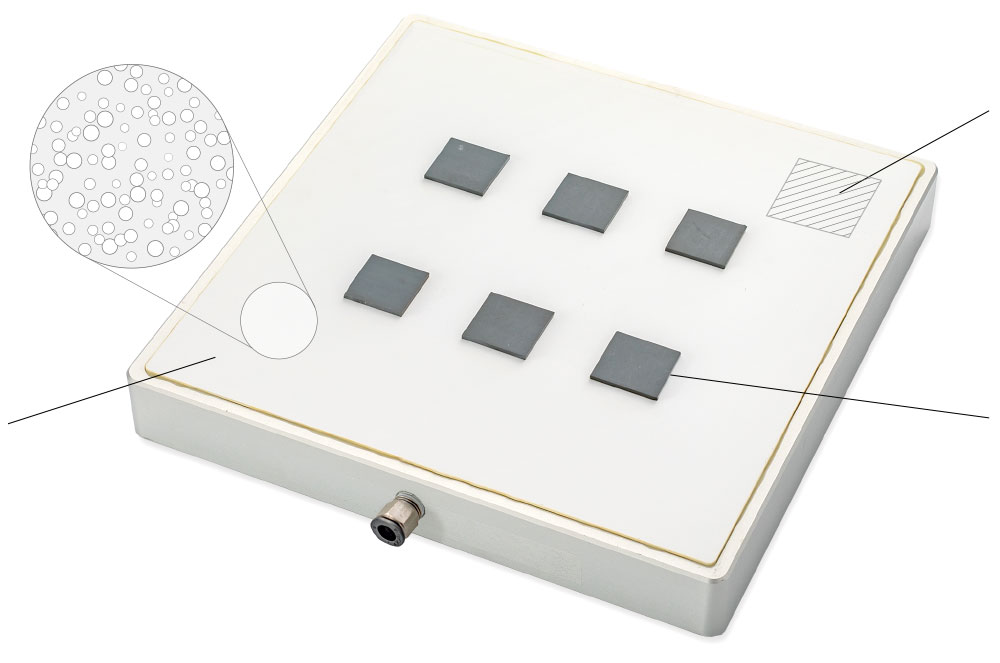

Pore size is flexibly controlled by material making and manufacturing technology. Stable material production is possible without pinholes or other abnormalities.

High-precision flat surface griniding that meets customer requirements. Stable accuracy can be maintained without material deterioration or dust generation over time.

The manufacturing technology that minimizes air leakage creates a high degree of vacuum and strongly adsorbs the workpiece.

Nishimura Ceramics is characterized by the fact that “every day is research and development. In addition to uniformly porous ceramic products, we have developed and manufactured all kinds of ceramic products, including insulating, heat-resistant, pressure-resistant, low-reflective, highly reflective, light-transmitting, heat-absorbing, and heat-radiating products. Combining tens of thousands of different raw materials, mixing ratios, and firing methods, we create prototypes of more than 100 different materials in a single year.

Nishimura is actively involved in prototyping, development, and joint development with our customers. With the know-how of ceramics manufacturing cultivated over the years since our establishment in 1918, we can make best proposal from the design and development stage.

Nishimura offers a demonstration model of ANYCHUCK. Since the optimum specifications vary depending on the customer’s work and workflow, we would be happy to consult with you and conduct a hands-on test with the demo machine.

Contact us