Product

-

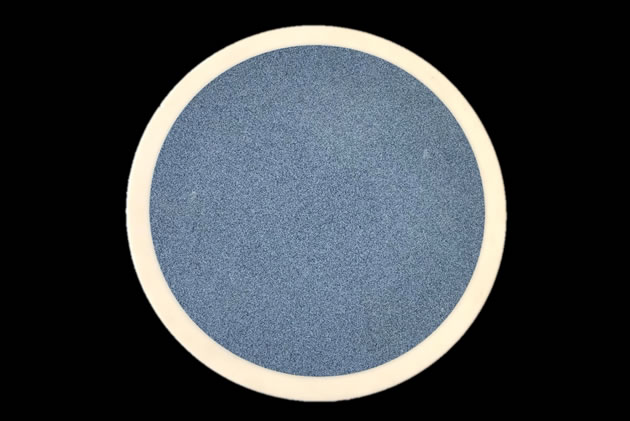

Partial adsorbing porous vacuum chuck VM-6 / Ceramic vacuum chuck

Ceramics vacuum chuck only adsorbs and pins down an object that covered all surfaces of the vacuum chuck, however, VM-6 can adsorb and pin down many smaller objects at once

-

Ceramic heat sinks and LED parts

Nishimura Advanced Ceramics propose the use of N-9H and N-6H ceramics for heat sinks and LED parts because with their high thermal conductivity.

-

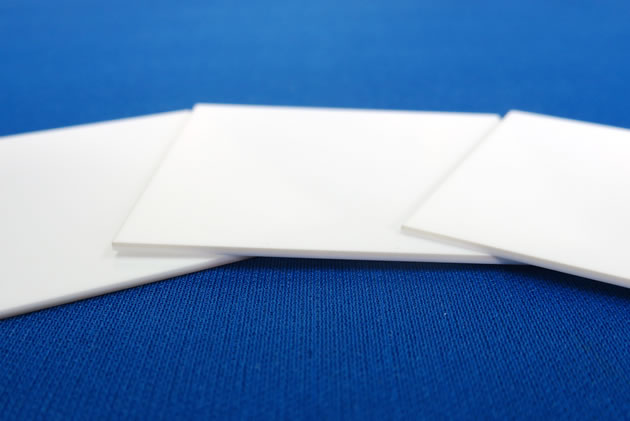

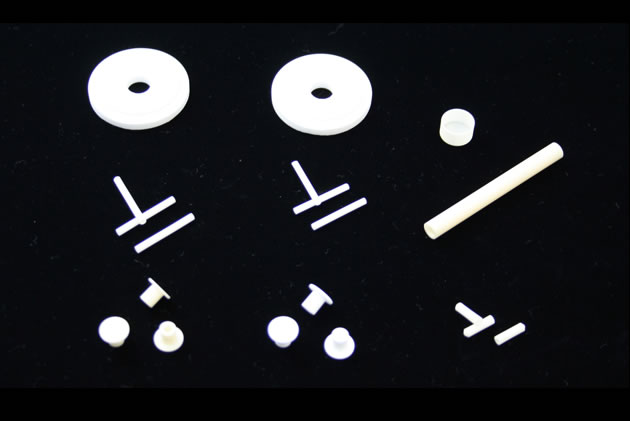

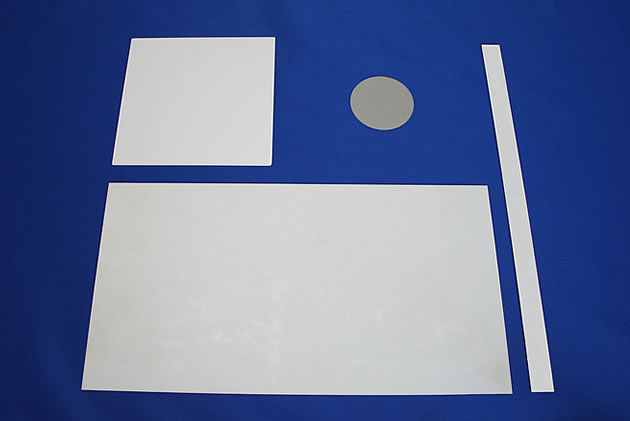

Ceramic Square plate ,Round bar,Round Plate

Square Plate:Nishimura produce the fine ceramics by machine press.

Round bar:Nishimura produce a round bar by extrusion molding. It is suitable for structure material.

Round Plate:Nishimura have an original metal mold of round plate. -

Ceramic substrate size list (Alumina 96%, Aluminum Nitride 170W, Zirconia, ZTA)

Alumina ceramic substrate produced by tape casting method.

We accept order down from one piece! -

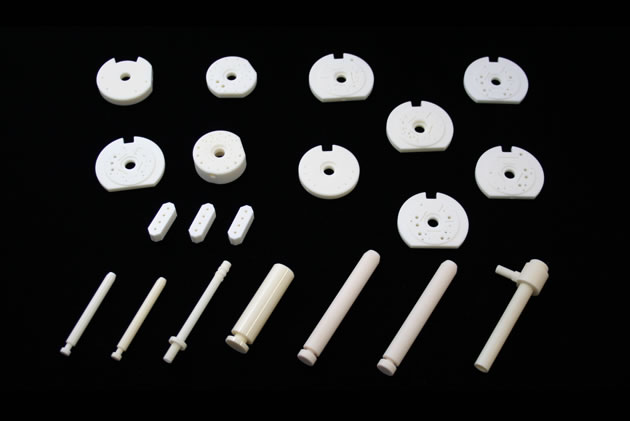

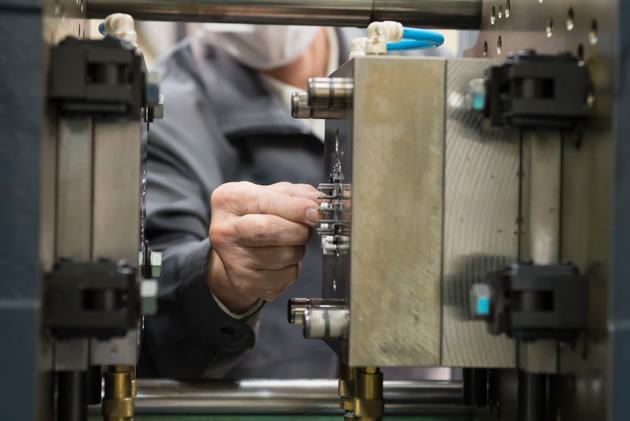

Ceramic parts for medical equipment and analyzers

Nishimura Advanced Ceramics produce stators, metering valves, cylinders, and pistons for medical diagnostic equipment and analyzers. High purity alumina powder is the main materials for those parts. These products and our manufacturing can satisfy all requirements for ceramic parts for medical equipment and analyzers.

-

Micro Porous Alumina Ceramics, Nano porous ceramics

Nishimura Advanced Ceramics produce porous Alumina in levels of micro porous ceramics and nano porous ceramics.

customize porosity and pore size according to customer’s requests.

-

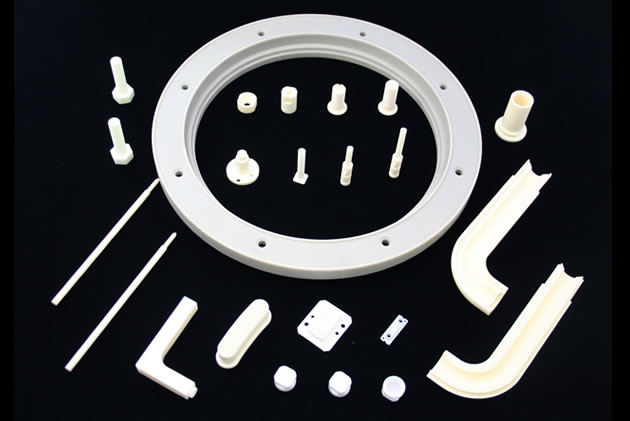

Ceramic parts for semiconductor and liquid crystal manufacturing machines, and for solar equipment

Manufacturing machines of semiconductors required material with high rigidity, processing accuracy, seismic capacity, heat resistance, heat conductivity efficiency, surface processing accuracy, metal contamination, chemical resistance, gas resistance, plasma resistance,excellence insulation performance, electric permittivity, dielectric loss tangent, volume resistivity, low dust generation (particles), cost, etc.

Nishimura Advanced Ceramics propose that with the application of highly-pure Alumina (Al2O3 purity 99.5% to 99.99%), Aluminum Nitride (ALN), and Yttria (Y203), we can satisfy the requirements above.

-

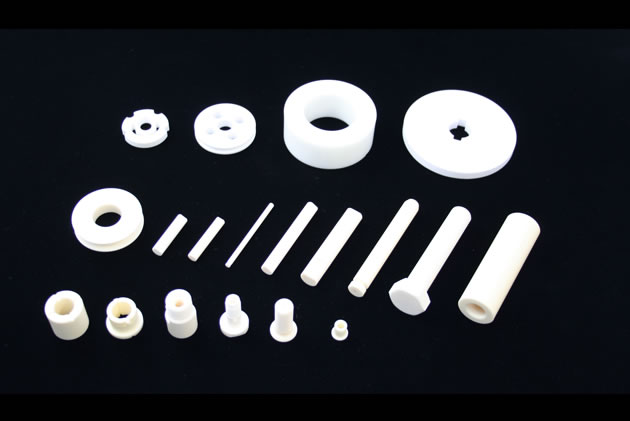

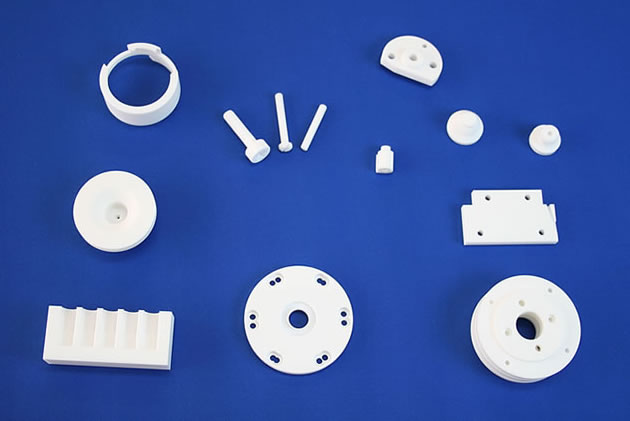

Ceramic machine parts and ceramic pump parts

Nishimura Advanced Ceramics propose the use of highly purified alumina ceramics for machine parts and pump parts.Highly pure alumina ceramics are extensively applied as an incredibly strong ceramic. It has excellent abrasion resistance, and there is no rival among other ceramic for its electrical insulation, chemical resistance and other abilities.

-

Ceramic For optical products

R&D team of Nishimura Advanced Ceramics had been inventing ceramic materials which have similar thermal expansion as other commonly-used materials.

recently, our original thermal expansion controlled ceramics has been selected by variety of customers, such as whom in camera industry.

-

Ceramic parts for temperature sensor parts

Nishimura Advanced Ceramics propose the use of N-9H, N-6H, an alumina and aluminum nitride for temperature sensor parts.

These ceramics are highly responsive and have excellent heat conductivity. -

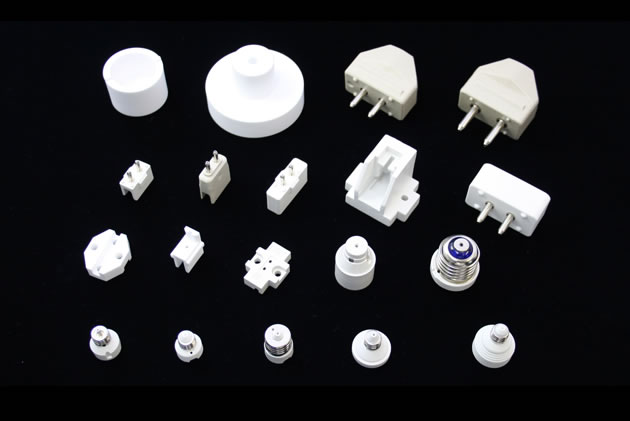

Ceramic lighting apparatuses

Nishimura Advanced Ceramics propose the use of zircon cordierite ceramics and cordierite ceramics, which have a low thermal expansion rate, high insulation performance and heat shock resistance, as ceramics for lighting apparatuses such as halogen lamps and HID lamps.

-

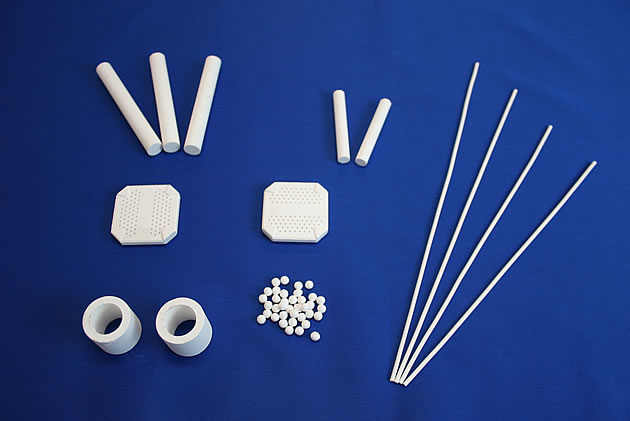

Ceramic insulators for heaters, crucibles and heat-resistant parts

Nishimura Advanced Ceramics produce various ceramics as heater insulators, crucible parts, and heat-resistant parts.

We comprehensively take the thermal expansion rate, heat shock resistance, hardness, heat conductivity, form, cost, and other requirements into consideration to provide the most suitable ceramic for you. -

Ceramic for power supply devices and insulators

Nishimura Advanced Ceramics propose zircon ceramics, zircon cordierite ceramics, and cordierite ceramics, which have excellent insulation, thermal shock resistance and pressure resistance.They are often used as power supply and insulator ceramics.

-

Arc extinguishing ceramic(Arc resistant ceramic)

Npc’s Arc resistant ceramic is made by Zircon. A high tension air circuit breaker and electro magnetic switch. Arc resistance ceramic is a excellent arc extinguish material and it is able to protect other parts from the arc heating.

-

For catalysts, antibacterial processing and water treatment

In the environment-related field, Nishimura Porcelain is manufacturing earth-friendly ecological ceramics.

-

Machinable ceramic

Precision, Quality, Machinability and Time-Effectiveness

All Combined As One — Machinable Ceramic -

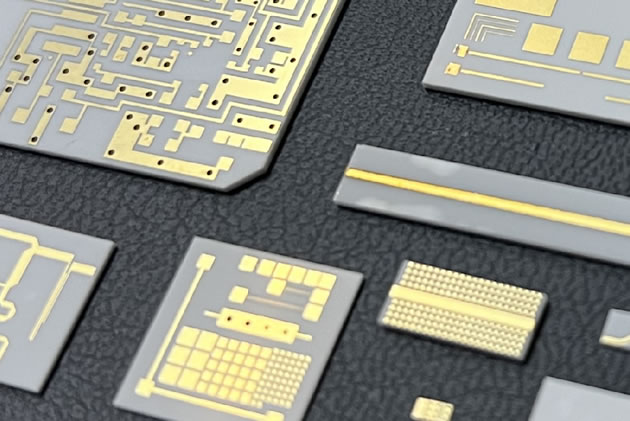

Ceramic Circuit Board

Nishimura produce ceramic circuit board. We print wiring diagram on a ceramic lamella.

Not only insulation but also it is useful in many ways since we have ability to make it comes true -

CIM(High-pressure Ceramic InJection Molding)

Nishimura Advanced Ceramics produce 1~4 piece of small and complex shaped parts in one shot by CIM(High-pressure Ceramic Injection Molding) technology. We are proud of ourselves as the pioneer of CIM(High-pressure Ceramic Injection Molding) since we started CIM technology from 1986.

-

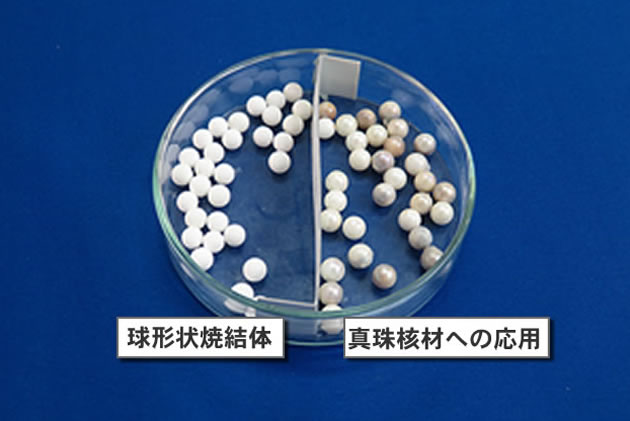

Apatite Bio Ceramic (Nano Freeze Dried Powder, CIM feedstock)

We have made apatite bio ceramic ball(diameter 10mm) by CIM, and confirmed performance of our Pearl core.(Patent No.2958579)

Please check SEM picture and properties below.Left side of the picture is original apatite ball, Right side of the picture is apatite ball after pearl shell processing.

-

Large Size Advanced Ceramics (N-999, AlN, Zirconia)

Nishimura Advanced Ceramics is always researching and challenging to produce large size ceramic material stably with lower cost. Day by day we are brushing up the manufacturing process and material mixing for finding better manufacturing process.

-

High purity Alumina ceramic crucible, Aluminum Nitride ceramic crucible

NPC can produce high-quality Alumina/Aluminum Nitride ceramic crucible in any shape or a better price according to your need.

-

Mo-Mn Metallised ceramics

These Metallised ceramics are made of Alumina ceramics and silver coated with Mo-Mn +Ni layer on the surface. By using this technique, Metal parts and ceramics parts can be combined. Using this technique can be used a wide range of materials, From 92% Almina to 99% .

-

Hot Press Ceramics

This is the most cost-effective method of producing ceramics with complex shapes.

-

Thin Film substrate

Thin film deposition system that combines film deposition technology using sputtering and vacuum evaporation with photo-etching technology, and a thick-film process using screen printing methods, and is capable of metallising, patterning and forming wiring of various metal films on ceramics and glass materials.

-

[High-performance power saving] Hearth Liner

Nishimura Ceramic recommends aluminum titanate, which has excellent thermal shock resistance, as the most suitable material for hearth liners for aluminum deposition.We have supplied our products to the Institute of Laser Engineering, Osaka University and received feedback on thermal shock resistance and power saving.

![[High-performance power saving] Hearth Liner](https://nishimuraac.com/web/wp-content/uploads/pc-hearthliner.jpg)