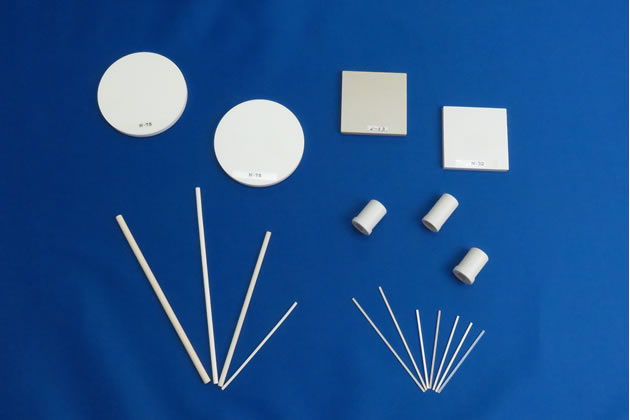

Product sample image

Product sample image

Features:

- Insulating ceramics with low dielectric loss in the GHz and MHz bands.

- Various materials are available, including low dielectric constant (ε), low dissipation factor (tanδ), and high-strength types.

- Nishimura’s production process allows us to produce simple shapes like plates and small and complex ones. We can also provide it as a filler.

Applications:

- 5G mobile communications.

- Aerospace, radar, microwave, etc.

- Next-generation telecommunications field, medical field.

- Substrate materials for high frequency with heat resistance and durability, antenna materials, RF windows, and materials for semiconductor manufacturing equipment.

Properties of Low Dielectric Loss 10GHz Band (10-5)

| NAC No. | N-99DLT | N-999DLT | N-99 |

| Dielectric Constant ε | 9.85 | 9.82 | 9.668 |

| Dielectric Loss tanδ (×10-5) |

2.7 | 1.0 | 23 |

Measured by Split cylinder method

Properties:

| NAC No. | N-99DLT | N-999DLT | N-75 | N-600 | |

| Material | Alumina(Aℓ2O399.7%) | Alumina(Aℓ2O399.9%) | Forsterite | Cordierite | |

| Bulk Density | g/cm3 | 3.93 | 3.95 | 3.0 | 2.5 |

| Water Absorption | % | 0 | 0 | 0 | 0 |

| Flexural Strength | MPa | 289 | 348 | 150 | 150 |

| Young’s modulus | GPa | 388 | 392 | ━ | ━ |

| Linear Thermal Expansion Coefficient(30~300℃) | ×10-6/℃ | 8.97 | 0.98 | ||

| Volume Resistivity | Ω・cm | > 1016 | > 1016 | > 1013 | > 1014 |

※The values above are not guaranteed values but representative values.

Comparison Graph of Dielectric Loss and Dielectric Constant (Millimeter Wave Band)

We measured dissipation factor and dielectric constant of various ceramics materials, targetting the millimeter wave band which is growing in demand. Measurement was done by EM labs, Inc.

EM labs, Inc. https://www.emlabs.jp/

Low-loss tangent Alumina Dissipation factor(tanδ・DF)Measurement(Millimeter Wave band)

Dissipation factor

(tanδ・DF)Measurement(Millimeter Wave band)

Measurement(Millimeter Wave band)

Related Pages

|

Characteristics Comparison List : Compare by Dielectric Constant |