”Working together to achieve infinite quality improvement”

Under this quality policy, Nishimura Advanced Ceramics has been working hard together to improve quality everyday.

Commitment to High Quality and Assurance

We have established a quality management and quality assurance system based on ISO9001, IATF16949 (international standards for quality management systems specific to the automobile manufacturing field), and KES (standards for environmental management systems originating from Kyoto, the birthplace of the Kyoto Protocol). We are continuing to take the following initiatives.

- Establishment of a quality assurance system tailored to the customer’s industry by our quality assurance department

- Ensuring thorough traceability

- Conducting internal audits and supplier audits

- Implementation of regular quality meetings

- Bottom-up quality improvement system through QC circle activities and improvement proposal system

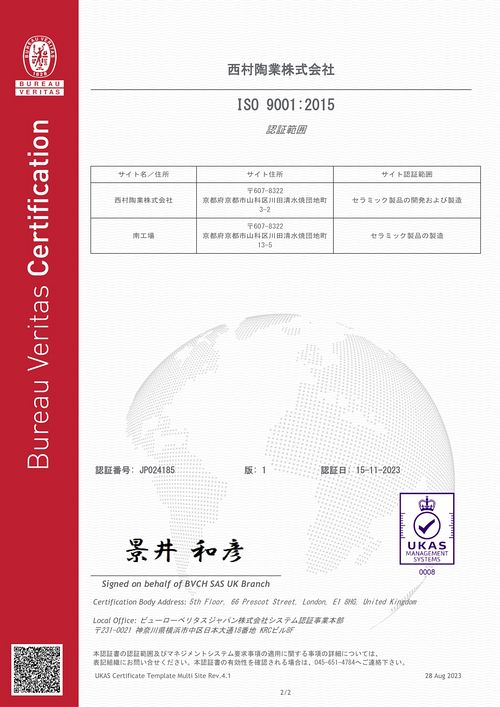

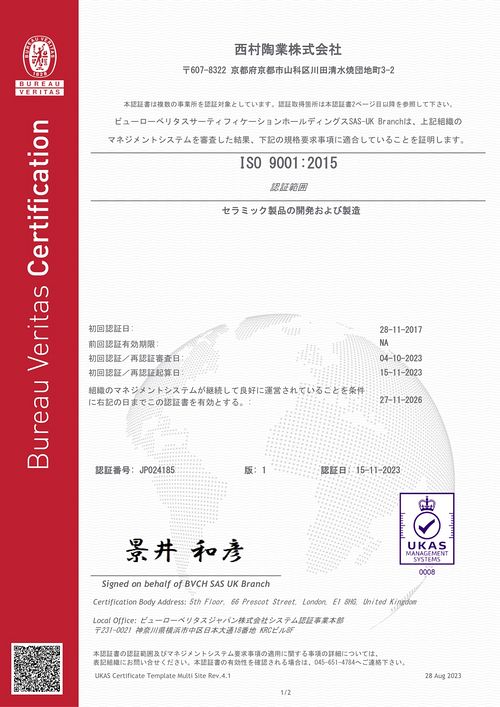

ISO9001 Certification

|

|

Initial certification date: November 28, 2017

Certification number: JP024185

Auditing organization: BV

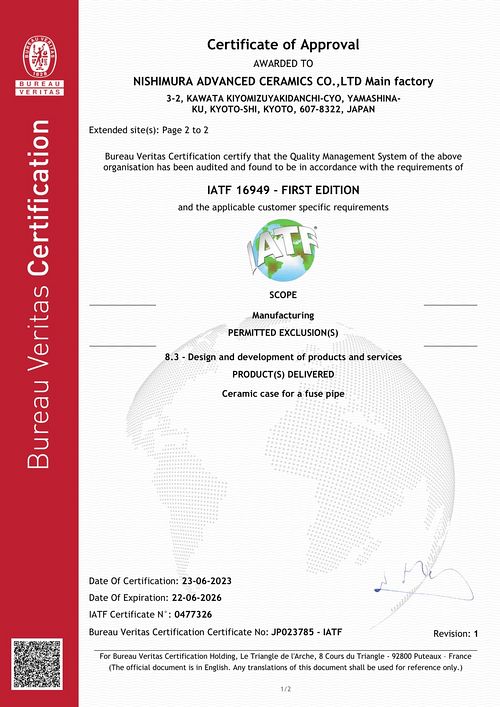

IATF16949 Certification

|

|

Initial certification date: June 23, 2023

Certification Number: JP023785-IATF

Auditing organization: BV

KES Certification

|

Initial certification date: March 1, 2007

Certification Body: KES Environmental Organization, a non-profit organization

About our inspection system

Full range of measurement equipment

To achieve flexible and more accurate inspections, we take advantage of each characteristic and using them for different purposes.

Some examples are introduced on the analysis and evaluation page.

Introduction of inspection system to prevent human error

We have adopted a system that allows wireless transmission of measurement results from calipers and micrometers to a PC, and automatic issuance of inspection sheets.

Utilization of Statistical Data

We have a system to store and manage inspection data. By understanding the trends in numerical variations and the movement of numerical values from lot to lot, we can manage and improve quality.

- Introduction of SPC (statistical analysis) management system

- Automatic calculation of Xbar-R / Xbar-s control charts, histograms, Cp/Cpk (process capability index), etc.

- Close lot control

|

|

Analysis & Evaluation

We have a cooperative system with public testing and research institutions such as the Kyoto Municipal Industrial Technology Research Institute, the Japan Fine Ceramics Center (JFCC), and other public testing and research institutes, and can provide SEM, component analysis, X-ray observation, and other services.

Nishimura Advanced Ceramics will keep on working hard to improve quality.