| Facilities introduction |

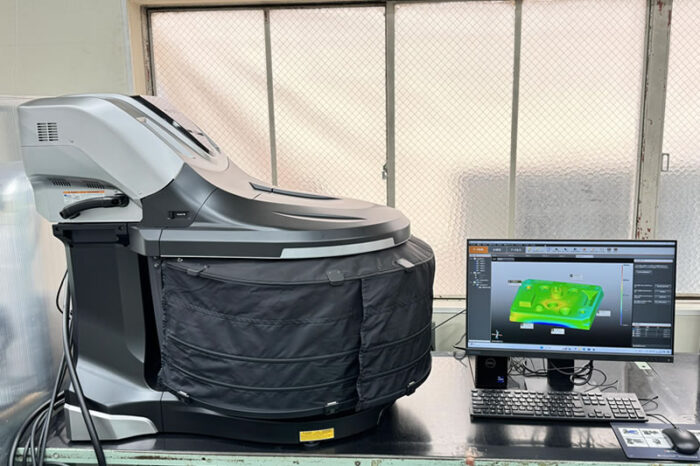

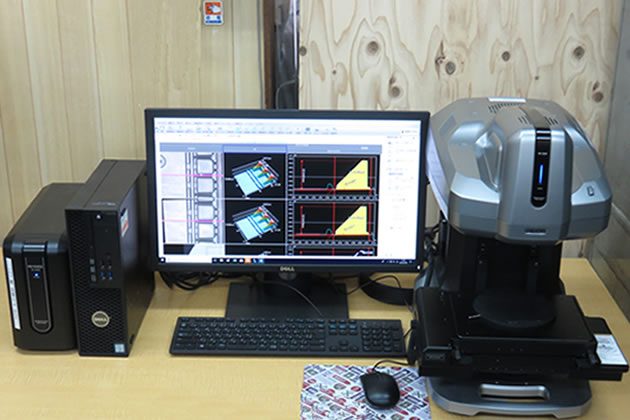

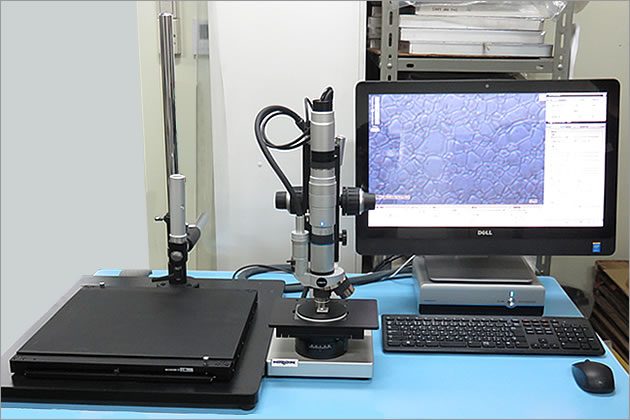

To provide better services and products, it is important to have different measuring devices specific for evaluation. Here is the information of our evaluation machine.

Check the facility introduction from here

Collaboration with KYOTO MUNICIPAL INSTITUTE OF INDUSTRIAL TECHNOLOGY AND CULTURE

Nishimura Advanced Ceramics is collaborating with the Kyoto Municipal Institute of Industrial technology and culture(KITC)

Below systems are installed at KITC

- X-ray fluorescence

- Thermal analysis equipment

- Thermal conductivity measuring apparatus

- X-ray diffractometer

- Scanning electron microscopy

A joint research project is often held between KITC and Nishimura to ensure product quality.

All Technical experiments are according to Japan Industrial Standard(JIS standard) as requested by Japan Fine Ceramics Center(JFCC)