|

|

Advanced Ceramic products for semiconductor, liquid crystal manufacturing machines, and for solar equipment

Manufacturing machines of semiconductors required material with high rigidity, processing accuracy, seismic capacity, heat resistance, heat conductivity efficiency, surface processing accuracy, metal contamination, chemical resistance, gas resistance, plasma resistance,excellence insulation performance, electric permittivity, dielectric loss tangent, volume resistivity, low dust generation (particles), cost, etc.

Nishimura Advanced Ceramics propose that with the application of highly-pure Alumina (Al2O3 purity 99.5% to 99.99%), Aluminum Nitride (ALN), and Yttria (Y203), we can satisfy the requirements above.

NPC’s ceramic manufacturing policy is producing high-density ceramic with tiny crystal composition. This policy match with the requirement from the semiconductor device industry because Nishimura low pore vacancy ceramics is suitable for plasma generation device.

Non-metal contamination grade Alumina is also widely used for front end semiconductor manufacturing.

Because of its features, those materials are used as:

-Domes

-Focus rings,

-Etching nozzles, Shield

-Shower head

-Chamber Liner

-Cover Ring

-Target machine

-Heater material

-Wafer table

-RF window

-Lifter Pin

-End effector/arm

-Deposition Ring

and so on.

Aluminum nitride(AlN) is excellent in heat conductivity, as an electrical insulation, heat radiation resistance and heat shock resistance. Furthermore, it has thermal expansion coefficient is similar to a silicon wafer.

Yttria is the material that has excellent plasma resistance.

All kinds of material/items are possible to order with customized design and small quantity.

Case Introduction

Plasma resistance Bell-Jar for CVD Material N-999S

|

We have chosen N-999S(Al2O3 99.9%) as material which showed great plasma resistance. This product is specify for semiconductor manufacturing device. |

Alumina Ceramic N-999S Ceramic tube with bending resistance

|

flawless inside diameter (under 0.2mm curvature deviation without polishing). size: φ10 +0/-0.05×φ8 +0.1/0×350L |

Hair pin tube plasma cover

|

This hair pin tube(U shape tube) is used as cover pipe for semiconductor manufacturing device. Material: N-99(99.7% Alumina) |

Translucent plasma cover

|

Nishimura’s N-9000NS translucent high strength alumina is used as plasma protection of semiconductor manufacturing device. |

Plasma proof ceramic elbow

|

Made by Nishimura high purity Alumina ceramics. |

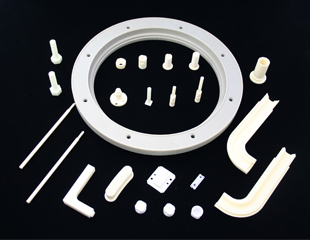

N-99 Semiconductor produce equipment parts

|

Alumina 99.7%. All the holes and channels were token by the green-machining method(unfired machining) |