Nishimura Advanced Ceramics produces porous Alumina in levels of micro-porous ceramics and nano-porous ceramics.

Customize porosity and pore size according to the customer’s requests.

pore size:φ0.1μm(100nm)~50µm

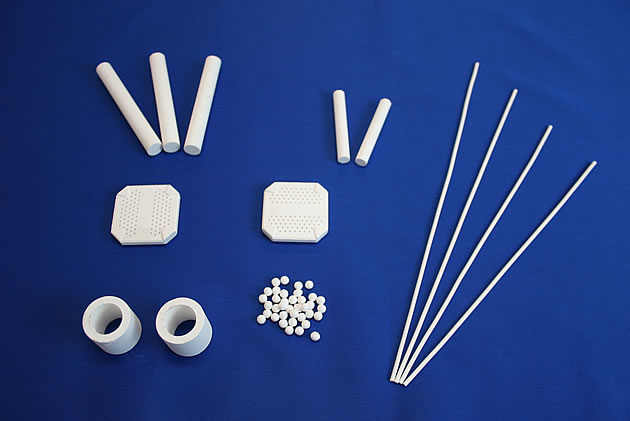

shape: ball, bar, plate, pellet. Customized products are also possible; feel free to ask here.

If you are looking forward to finding a vacuum chuck plate, please enter here.

Features of porous ceramic

- Passing liquid or gas through

- Lighter than other ceramics

- Outstanding small pore size 0.1um(100nm)

By these features, especially the outstanding small pore size of 0.1um, Nishimura’s porous ceramics can be applied in many ways.

Common applications of porous ceramics

- Liquid absorption.

- Liquid separation. After taking water repellent treatment, it can separate oil and water.

- Carrier of fragrance, deodorant, and germicide. It can support any liquid and keep it for a long time.

- Bactericide. It can support silver or another kind of germicide.

- Filter Porous ceramic is used as a liquid or gas filter/separator.

- Catalyst can keep platinum oxide. providing deodorization/decomposition of exhaust gas and also removing malodorous components.

- Nano bubble. It can be used as a nano-bubble generator. We can also arrange porosity, pore size, and type of shapes according tothe customer’s request. Please feel free to ask us if you are interested.

|

When we take the original water repellent treatment, the ceramic doesn’t soak up the water-based ink. |

Without the water repellent treatment, it absorbs water-based ink. |

The characteristic chart

| R-200 | R-203 | N-99EP | ||

| Main Composition(Al2O3) | 91% | 91% | 99% | |

| Bulk specific gravity | 1.5 | 1.6-1.7 | 2.5 | |

| porosity percentage | 55.0 | 51.0 | 35.4 | |

| pore size*(μm) | 1.4 | 0.7 | 0.1(100nm) | |

| Water absorption(%) | 35.0 | 30.0 | 14.0 | |

| Bending strength(MPa) | 200 | |||

| Max.Heat resistant temperature(℃) | 1100 | 1100 | ||

| Shape | Ball, Pellet, Round Bar, Square Bar, Pipe, Plate, Tube, and Customized Products. | |||

| Example | Liquid absorption | absorbs and keeps any liquid. | ||

| Liquid separation | After taking water repellent treatment, it can separate oil and water. | |||

| Carrier of fragrance, deodorant, and germicide. | It can support any liquid and keep it for a long time. | |||

| Bactericide | It can support silver or another kind of germicide. | |||

| Filter | Porous ceramic is used as a filter for liquids or gases for filter/separation. | |||

| Catalyst |

Catalyst can keep platinum oxide. providing deodorization/decomposition of exhaust gas and also removing malodorous components. |

|||

| Nano bubble | It can be used as a nano-bubble generator | |||

| Item stock number | N-99SP |

| Component | Alumina99.9% |

| Bulk specific gravity | 2.5 |

| Porosity | 35% |

| Pore size | 55nm (0.055μm) |

| Water absorption | 15% |

*Median pore diameter

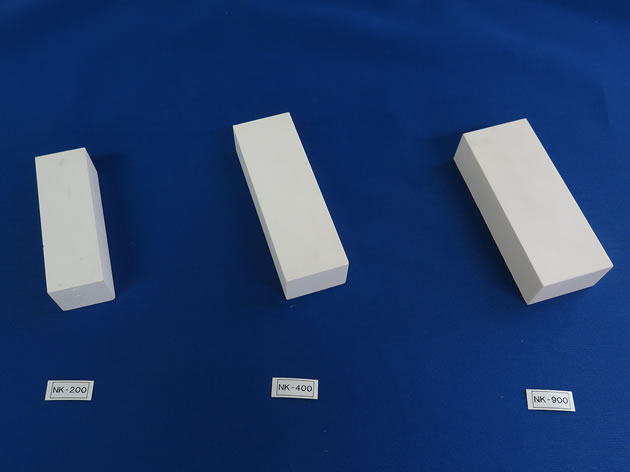

Large-pore porous ceramics(Available for large size)

This material is a porous ceramic that has a rougher pore size. Pore size (Median diameter) is 2~16μm. Porosity is higher as well.

It is available to make a Maximum size ∮of 500 mm.

| Materia No. | NK-200 | NK-400 | NK-900 | NK-1500 | Note |

| Material | Alumina | ||||

| Porosity % | 46.9 | 51.7 | 47.5 | 47.2 | JIS R1655 |

| Pore Size*(um) | 2.0 | 3.8 | 9.3 | 15.5 | |

| Shape | Square plate, Round plate, Square bar | ||||

| Usage | Vacuum chuck, Filter, and so on. | ||||

*Median pore diameter

R-200 Porous alumina crucible

We have made a crucible with R-200. This crucible is made by a mechanical press.

Therefore, it is possible to be purchased at a more affordable price.

It has very high water absorption, so it will support a liquid for a long time.

It is possible to support any kind of liquid, such as fragrance or silver liquid.

It will also work as a liquid separation.

Sample size φ40×50H

N-99EP nano-porous alumina crucible

N-99EP is Alumina 99% ceramic-based nanoporous ceramics produced in the Nishimura factory in Kyoto, Japan.

- Porosity 35%

- Pore size 0.1μm

- Water absorption 13.9%

Tiny Porous ceramics

4mm×4t 4mm×4t |

2.8mm×0.9t 2.8mm×0.9t |

Porous ceramics made by NK-3000W.

Commonly used as a vacuum chuck, suction pad, and filter.