High strength, High purity Alumina ceramics N-9000NS and N-9000T

Nishimura Advanced ceramics cooperated with the Medical analysis device industry for a long time, and we have succeeded to develop a special material for the medical industry. N-9000NS / N-9000T‘s average crystal size is under 1μm with 1.5~2 times higher intensity than other Competitors.

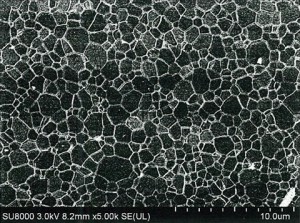

Nishimura NishimuraN-9000NS (×5000) |

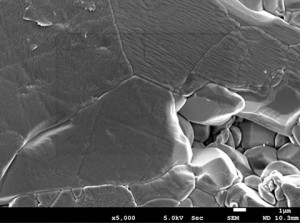

Competitor’s Alumina 99.5% Competitor’s Alumina 99.5%(×5000) |

The reason why our materials are suitable for the medical industry

(1)Excellent durability

This material has excellent wear resistance (Vickers hardness 21.4 GPa), medical product lifeaspan will be increased.

(2)Unbreakable

Bending strength, Compressive strength, Tensile strength is extremely high. It is the most suitable material for precision parts.

N-9000NS has similar/better material properties like Sapphire.

(3)Gentle for blood and easy for cleaning

Crystal size is under 1 µm which is an extremely smooth surface.

Since a red blood cell size is approx. 5 µm, it won’t be stuck on an Alumina crystal.

It’s very easy to wash, this material is suitable for parts/tools that required to be hygienic and repeatedly used.

(4)Chemical Resistance

The high purity Alumina material stands for most of Acid or Alkali. Especially N-9000NS and N-9000T have excellent chemical resistance.

(5)Plasma Resistance

This material is used as a plasma resistance material. Since Alumina purity of this material is very high(Al2O3>99.99%), grain boundary segmentation won’t occur.

(6)Excellent Insulation

Since this material doesn’t contain many impurities, dielectric breakdown voltage and volume resistivity are very high which means it has an outstanding thermal resistance and great insulation at high temperatures.

Comparison sheet of Medical Standard and Nishimura’s high-intensity Alumina ceramics.

| Evaluation Point | Unit | Nishimura High purity Alumina | (Reference) | |||

|---|---|---|---|---|---|---|

| N-9000NS | N-9000T | ISO 6474※1 | ASTM F603※1 | |||

| Bulk Density | g/cm3 | 3.99 | 3.99 | ≧3.94 | ≧3.90 | |

| Al2O3 | % | >99.99 | >99.99 | ≧99.5 | ≧99.5 | |

| MgO | % | 0.05 | 0 | ≦ 0.3 | ― | |

| Other | % | <0.01 | <0.01 | ― | ― | |

| Amount of SiO2+CaO+ Alkali Metal Oxide |

% | ― | ― | ≦0.1 | ― | |

| Amount of SiO2+ Alkali Metal Oxide |

% | ― | ― | ― | ≦0.1 | |

| Ave. Crystal size | μm | 0.95 | 0.95 | ≦4.5 | ≦7 | |

| Grain Boundary | μm | ― | ― | ≦2.6 | ― | |

| Bending Strength | MPa | 822 | 750 | ― | ≧400 | |

| Elastic Modules | GPa | 406 | 401 | ― | ≧380 | |

| Vickers Hardness | GPa | 21.4 | 18.8 | ― | ― | |

Literature 1:Pharmaceutical and Food Safety Bureau No. 1008001 Ministry of Health, Labour and Welfare

Drug and Foods Administration Dept., Medical Device Investigation Office(October, 8th, 2008)

Case introduction

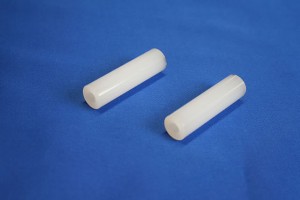

- Parts for dialysis machine(mainly tube)

Since it is translucent, it’s easy to check the blood flow. - Parts for mechanical parts (Tube,mostly Used as abrasion parts)

- Rotor/stator ceramic parts

- Bearing/ Sealing ceramic parts

- Alternative material from single-crystal Sapphire

Tube φ15×φ6×56L Tube φ15×φ6×56L |

Pipe φ4×φ2×170L Pipe φ4×φ2×170L |