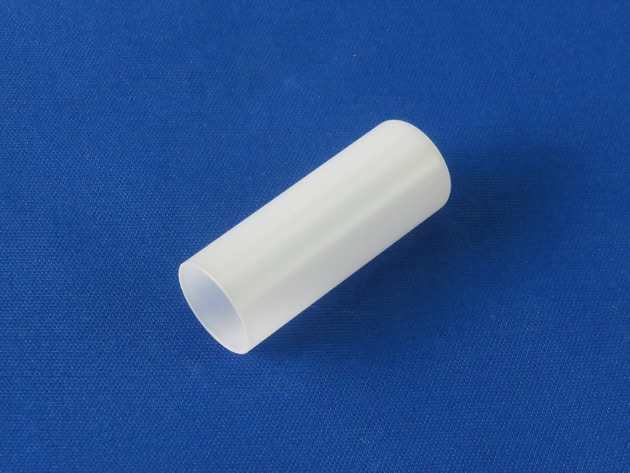

When manufacturing complex-shaped components such as rods, tubes, and things like that other than substrates and plates using single-crystal sapphire, processing costs tend to be very high because very hard material must be machined from cylindrical single-crystal ingots.

We propose N-9000NS high-strength translucent ceramics as a less expensive alternative material to single crystal sapphire.

Substituting N-9000NS high-strength translucent alumina ceramics, which have strength equivalent or superior to that of single crystal sapphire and can be manufactured from powder using a variety of molding methods, can achieve significant cost reductions.

Comparison sheet of N-9000NS and single crystal sapphire properties.

| Material | Alumina | Single Crystal Sapphire | ||

| Nishimura. NO | N-9000NS | ━ | ||

| Component (Al2O3) | >99.99% | Al2O3 99.99% | ||

| Color | Translucency | ━ | ||

| Bulk density | g/cm3 | 3.99 | ━ | |

| Water absorption | % | 0 | ━ | |

| Total Light Transmittance(JIS K7105) | % | 83.66% or more | Equal or superior | |

| Crystal structure | Polycrystal | Single Crystal | ||

|

Mechanical |

Vickers hardness | GPa | 21.4 | Equal |

| Bending strength | MPa | 820 | A little inferior | |

| Compressive strength | MPa | 5800 | Inferior | |

| Tensile strength | MPa | 213 | Inferior | |

| Impact bending strength | MPa | 0.7 | ━ | |

| Electrical Properties |

Volume resistivity | Ω・cm | 2.0×1016(20~100℃) | Equal |

| Dielectric contabt (1MHz) | 10 | ━ | ||

|

Dielectric loss tangent (1MHz) |

<0.001 | Equal | ||

| Dielectric strength | kV/mm | >10 | ━ | |

| Te value | ℃ | 1000 | ━ | |

| Thermal Properties |

Thermal expansion coefficient | 10-6/℃ | 8.2 | ━ |

| Heat thermal conductivity | W/m・K | 37 | ━ | |

| Max. operation temperature | ℃ | 1200 | ━ | |

| Thermal shock resistance | ℃ | 200 | ━ | |

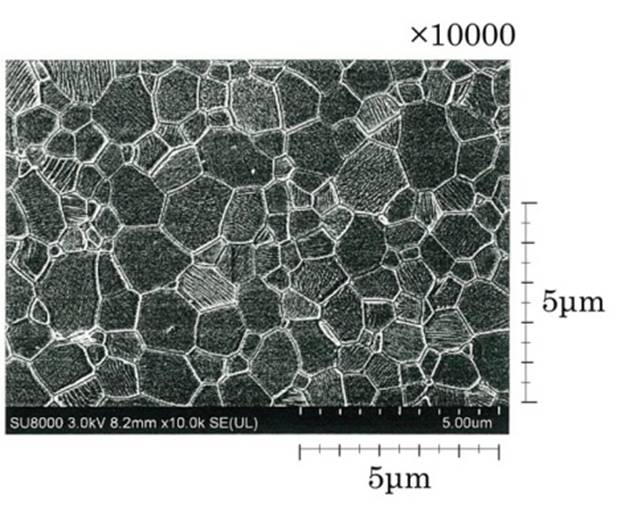

N-9000NS Crystal Photo

Why can it be manufactured at low cost?

| N-9000NS | Single Crystal Sapphire |

| Can be processed in a soft state before sinter. |

Can only be machined from ingots. |

| Injection molding is possible. | |

| Press molding is possible. |

Applications and markets

-

As parts for semiconductor manufacturing equipment: rings, plates, rods, tubes

-

As parts for medical manufacturing equipment

-

As a replacement for chemical-resistant sapphire parts

-

As a replacement for quartz parts

-

As a replacement for sapphire balls