|

|

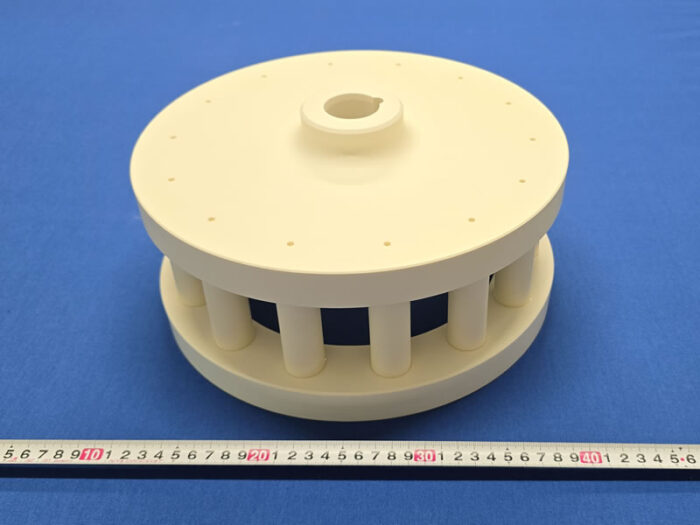

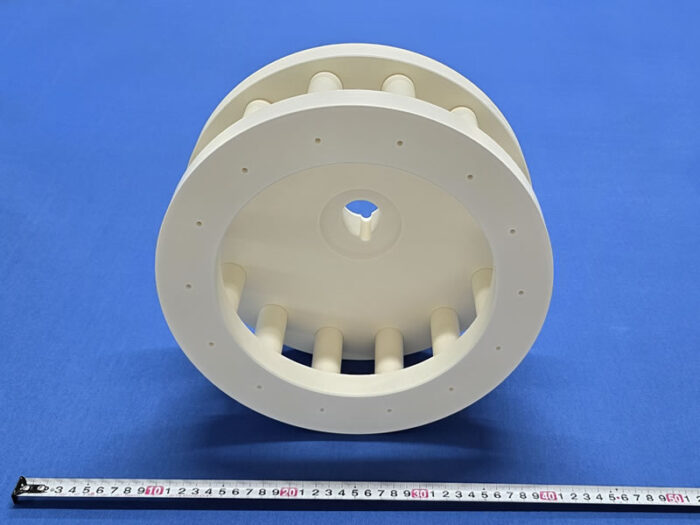

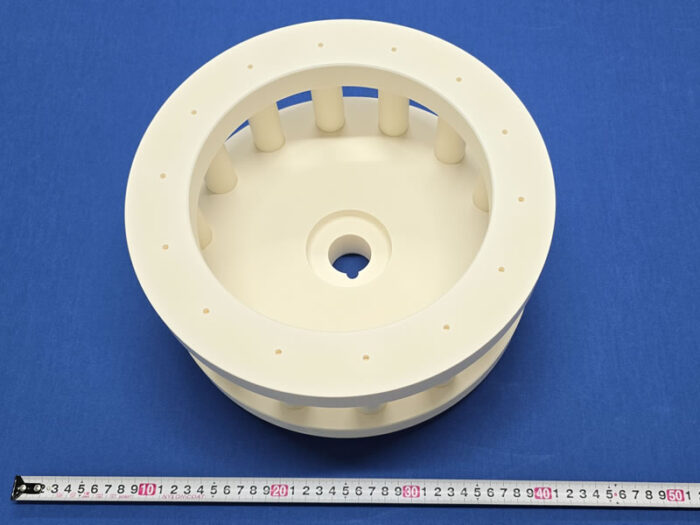

Our Alumina Rotors for Ceramic Pulverizers and Crushers are made with 99.7% high-purity alumina ceramics, ensuring exceptional wear resistance and long-lasting performance. Each rotor is custom-made to your specifications, including size and design, and is assembled with precision gluing for durability.

Key features

- 99.7% pure alumina is used for superior durability and high-temperature resistance.

- It uses Cold Isostatic Pressing (CIP) for uniform strength and precision molding.

- High-density ceramics with a minimum density of 3.9g/cm³ ensure high-performance operation under demanding conditions.

Applications of Alumina Rotors for Ceramic Pulverizers and Crushers

Alumina rotors for ceramic pulverizers and crushers are used in various applications, including:

1. Crushing and Pulverizing Processes

Ceramic pulverizers and crushers are utilized to grind raw materials and substances into fine powders, particularly in environments where wear resistance and high-temperature resistance are essential.

Alumina rotors, known for their high hardness, offer superior wear resistance compared to other materials, providing long-lasting performance and high efficiency.

2. Manufacturing Industry (Ceramics and Powder Metallurgy)

These rotors are used in the manufacturing processes of ceramics and powder metallurgy to micronize raw materials. Due to their purity, alumina helps maintain product quality, making them suitable for precision processing.

3. Mining Industry

Alumina rotors are employed to crush mined ores and minerals, facilitating subsequent refining processes. Their durability allows them to withstand harsh conditions and prolonged use.

4. Chemical Industry

In the chemical industry, alumina rotors are used to finely grind and pulverize chemical materials and raw substances. Their chemical stability and corrosion resistance make them suitable for long-term use with aggressive chemicals.

5. Food and Pharmaceutical Industries

These rotors are also utilized in the production processes of food and pharmaceuticals, where raw materials are finely processed. The high purity of alumina minimizes the risk of contaminating products with impurities, making them ideal for industries requiring high quality.

In summary, alumina rotors are used across various industries due to their high durability, chemical stability, and wear resistance.

Our custom rotors are designed to meet the needs of your milling and crushing applications. Contact us for more information or to discuss your specific requirements.

|

Related pages Listing by Characteristics: Wear-resistant ceramics |