|

|

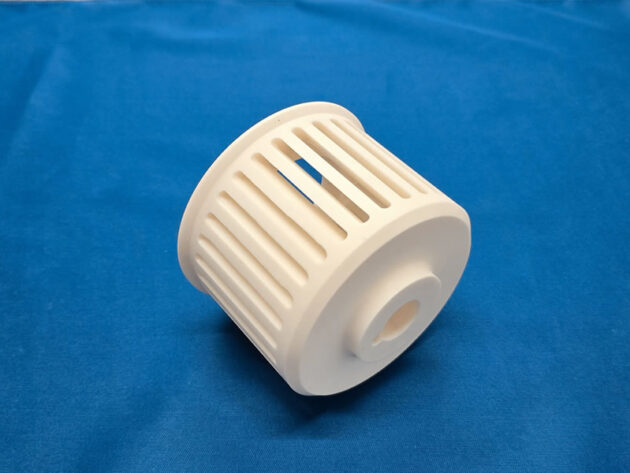

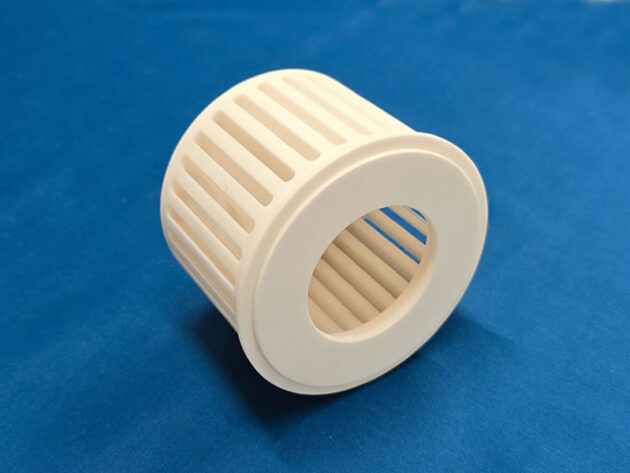

φ100×85L

We offer custom-manufactured ceramic rotors made from 99% pure alumina, designed for high-performance classification and grinding applications.

📐 Product Specifications

- Material: 99% Alumina

- Outer Diameter: 100 mm

- Length: 85 mm

- Structure: Monolithic (single-piece) design

- Manufacturing Method: Cold Isostatic Pressing (CIP)

- Density: ≥ 3.9 g/cm³

- Production: Made to order, customizable to your specifications

🔬 Key Applications

1. Grinding & Pulverizing Systems

Ideal for ceramic and mineral grinding machines, where high wear resistance and thermal stability are essential. Alumina rotors offer superior hardness and extended service life compared to conventional materials.

2. Advanced Manufacturing (Ceramics & Powder Metallurgy)

Used in processes requiring ultra-fine powder production. The high purity of alumina ensures minimal contamination, making it suitable for precision manufacturing.

3. Mining Industry

Effective in crushing and processing mined ores. The rotor’s durability supports long-term operation in harsh environments.

4. Chemical Processing

Resistant to corrosion and chemically stable, alumina rotors are well-suited for handling reactive or corrosive materials during fine grinding.

5. Food & Pharmaceutical Industries

High-purity alumina minimizes contamination risks, making it ideal for sensitive applications where product quality and safety are critical.