|

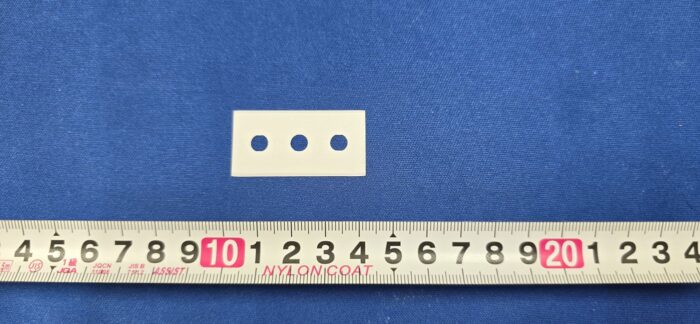

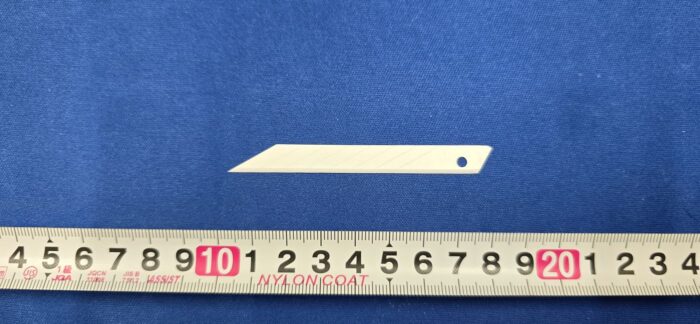

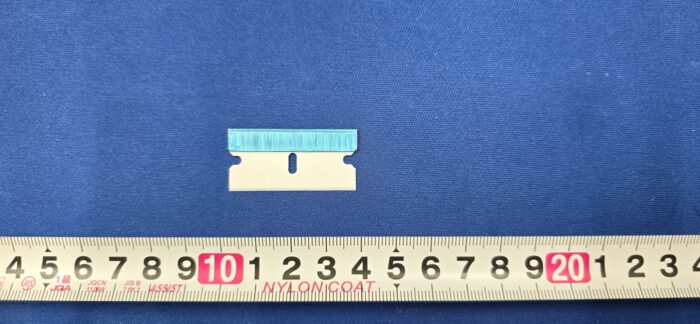

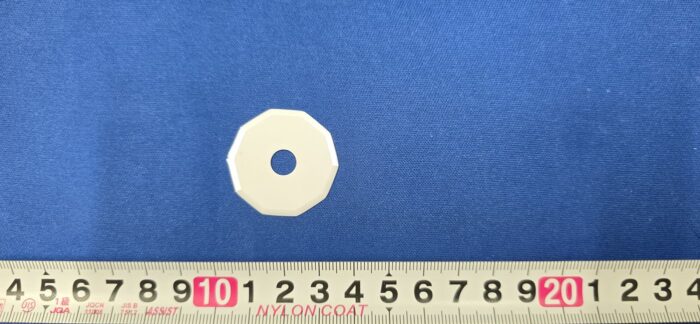

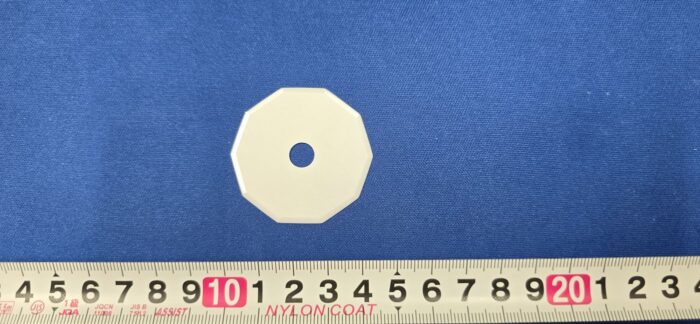

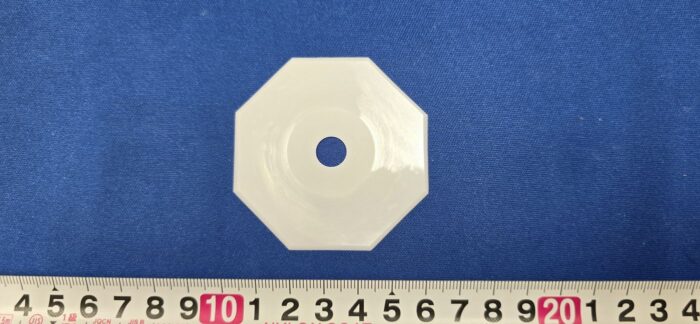

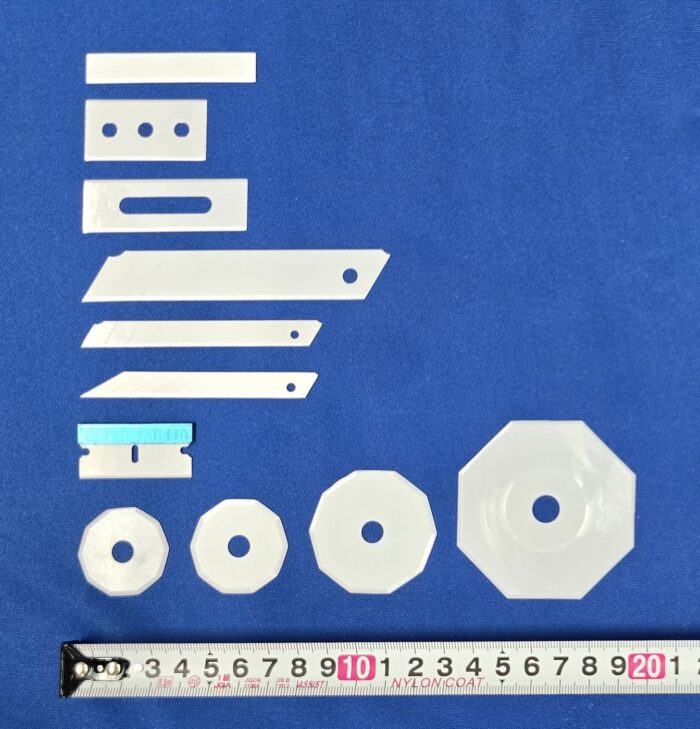

Ceramic cutter blades and ceramic razors Material: Zirconia

|

Features:

- More durable than metal blades due to superior abrasion resistance

- Rust-free

- Electric insuration

- Quick delivery

- Low cost

- MOQ 100 pieces~

Applications of Ceramic Blades

-

Alternative to Metal Blades

- Industrial Use: Ceramic blades are used for high-precision cutting of hard materials such as metals, plastics, and wood. They are characterized by their higher hardness and wear resistance compared to metal.

-

Medical Applications

- Surgical Instruments: Ceramic blades may be utilized in scalpels and cutters used during surgeries. They are also used as materials for high-frequency scalpels. Ceramic is an ideal material due to its sharp cutting ability and biocompatibility.

-

Chemical Industry

- Laboratory Equipment: Ceramic blades are used as cutters in chemical analysis and testing, especially where chemical resistance is required. They are strong against corrosion, making them safe to use in environments that handle chemicals.

-

Food Industry

- Food Processing: Ceramic cutters may be used for slicing and cutting food items. Their antibacterial properties and cleanliness make ceramic advantageous in this application.

-

Electronic Devices

- Semiconductor Manufacturing: Ceramic blades are used as hole-punching tools for copper lead frames.

|

関連ページ |