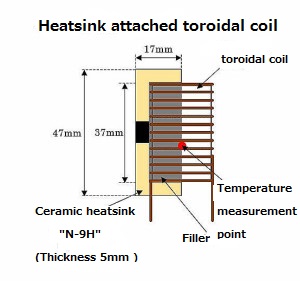

A toroidal coil will have better performance by attaching our ceramic heatsink ‘N-9H’ because the heatsink will radiate heat about 18℃ and it is estimated that 12A of electrical current will be applied.

Not only a magnetic line of force but the heat will be produced by sending a current to a toroidal coil. These accidents below may occur by generating heat.

- The electrical resin of a coil may deteriorate by heat and short.

- A toroidal coil may be damaged by the deterioration of glue.

- The magnetic characteristic will get lower if a core exceeds curie temperature(Transition temperature which ferromagnetic substance turn into a paramagnetic substance)

- The coil may fall from a board by melting of solder

- The measurement result of the temperature of the inner part of a coil when the ceramic heatsink “N-9H” was attached to a toroidal coil is written below.

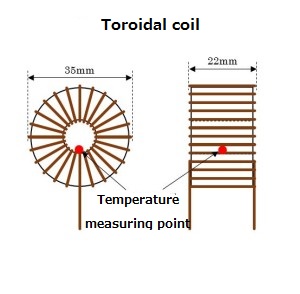

Measurement sample

Toroidal coil (rated current: 8A)

|

|

Measuring method, result

Measuring the temperature of the inner part of a coil when conducting electricity on the condition below.

(Condition) Voltage: 20V Current: 8A Electric power:160w Conducting time:1hour

Without ceramic heatsink “N-9H”

→The temperature of the inner part of a coil: 68.1℃

With “N-9H” on the toroidal coil and alumina filler “C-10S” between coil and heatsink

→The temperature of the inner part of a coil: 49.6℃