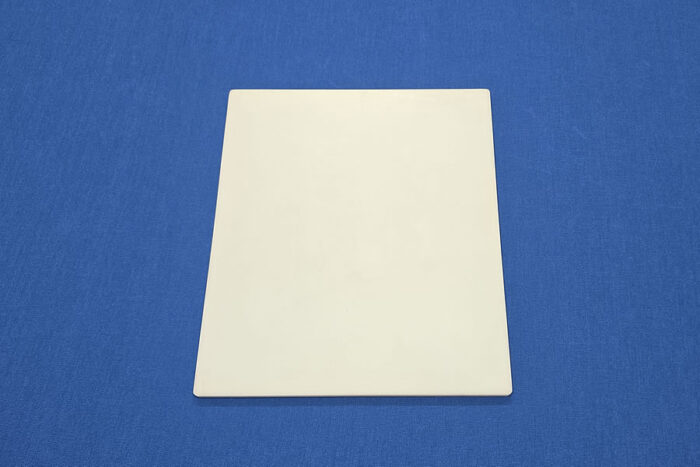

240mm×280mm

High-Purity Y₂O₃ Plates for Plasma & Semiconductor Applications

Large-Format Yttria Ceramic Plate Manufacturing

We are now capable of manufacturing large-format yttria ceramic square plates up to 240 mm × 280 mm, enabling support for a wider range of applications in semiconductor manufacturing, plasma processing, and vacuum systems.

Through precise sintering control, we achieve both high dimensional accuracy and uniform density, even in large ceramic plates where consistency is technically challenging.

Product Specifications

- Material: High-Purity Yttria (Y₂O₃)

- Size: Up to 240 mm × 280 mm

- Thickness: Available in thicknesses of 10 mm or less

- Water Absorption: 0%

These specifications make our yttria plates suitable for structural ceramic components operating in harsh environments.

Properties and Applications of Yttria Ceramics

Yttria (Yttrium Oxide, Y₂O₃) is an advanced fine ceramic material known for its excellent chemical stability at high temperatures.

It offers superior plasma resistance and corrosion resistance, making it ideal for demanding industrial environments.

Typical applications include:

- Semiconductor manufacturing equipment components

- Plasma etching fixtures and jigs

- Vacuum chamber inner walls and liners

- Plasma-exposed structural ceramic parts

Compared to other oxide ceramics, yttria exhibits minimal reactivity with metals, reducing contamination risk in sensitive processes.

High-Purity, Structural-Grade Yttria Ceramics

At Nishimura Ceramic Industry, we manufacture yttria ceramic components using high-purity raw materials (≥99.9% purity).

Our products are designed as structural-grade ceramics with zero water absorption, ensuring reliability and long-term stability.

While low-cost yttria grades with measurable water absorption exist in the market, such materials are not suitable for structural or high-reliability applications.

Our yttria plates are engineered specifically for critical industrial and semiconductor uses.

|

Related page Material:Yttria |