Zirconia

Zirconia (ZrO2) is a hard and tough solid solution combined with Zirconia and a small amount of Yttrium.

With its good wear resistance, electric insulation, and chemical resistance, Zirconia is commonly used as wear-resistant components and machine parts.

The thermal conductivity of the zirconia is very low (3w/m・K). Therefore, it can also be applied as a heat insulator.

Pros

Tough

Wear resistance

electric insulation

chemical resistance

Usage

Engineering parts(Bolt and Nut)

Cutter

Crushing mills ball

Connecting components for Optical fiber

Ceramic knife

Accessories

Positioning/Location pin

Ornaments

Pin or Shaft

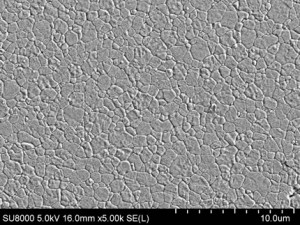

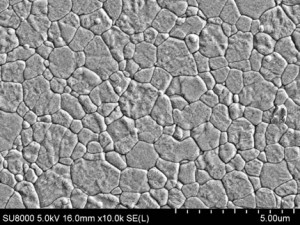

SEM picture of N-650 Zirconia

X5000 X5000 |

X10000 X10000 |

N-650 Zirconia engineering ceramics

N-650B Black Zirconia engineering ceramics

|

Nishimura advanced ceramics produce black colored zirconia ceramics. Commonly used as machine parts, optical parts, spindles and looms parts, and measuring equipment. It is also used for ornaments. |

N-660B Blue Zirconia engineering ceramics

|

Nishimura advanced ceramics produce blue zirconia ceramics. It is commonly used as machine parts, optical parts, spindles and looms parts, and measuring equipment. It is also used for ornaments. |

N-650H Hipped Zirconia engineering ceramics

Highest Fracture toughness Zirconia N-632

|

This is a Zirconia that has fracture toughness 8.9MPa・m1/2 Zirconia(Approx.1.5 times higher fracture toughness than usual Zirconia) It can be used as a case for a digital device, cutting tool, positioning pin, measuring probe, and more. We have dropped this plate from 2nd floor of our office, please check video below. |

| Bending Strenght | MPa | 1020 | |

| Fracture Toughness(SEPB) | MPa・m1/2 | 8.9 | |

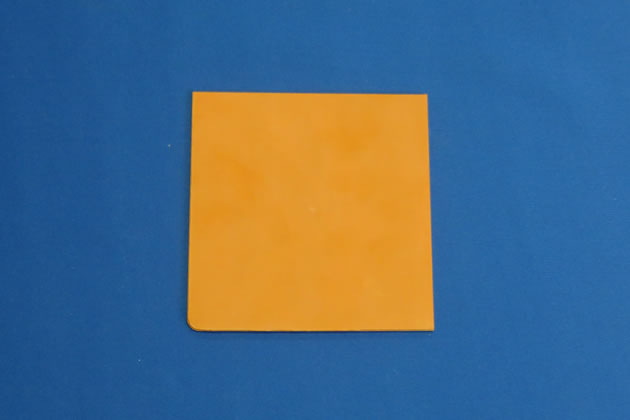

Orange color Zirconia

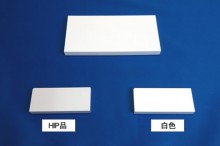

Alumina Toughened Zirconia (ATZ)

|

Combined of Zirconia oxide and 10-20% alumina oxide. |

| HIP ATZ | ATZ | |||

| Color | Glay | White | ||

| Flexural strength | MPa | 1700 | 1200 | |

| Fracture toughness(SEPB) | MPa・m1/2 | 4~5 | 4~5 | |

Translucent Zirconia

|

One of the unique material by Nishimura. High translucency without losing any fracture toughness, bending strength and hardness. |

8Y Zirconia

|

Yttrial 8mol% Zirconia

Application: Sensor use

Related page: 8Y Zirconia injection molding parts (CIM) |

CaO stabilized Zirconia

|

commonly used as crucible of platinum. Possible to function at over 2000℃ condition. |