Nishimura Advanced Ceramics specializes in high-performance Aluminum Nitride (ALN) ceramics, offering multiple grades tailored for advanced thermal management applications.

- ALN-170 – Standard grade Aluminum Nitride (thermal conductivity: 170W/mK)

- ALN-200 – High thermal conductivity Aluminum Nitride (thermal conductivity: 200W/mK)

- ALN-250 – Ultra-high thermal conductivity Aluminum Nitride (thermal conductivity: 250W/mK)

- ALN-HY0 – High-purity grade with no auxiliaries (thermal conductivity: 90W/mK)

Advantages of Aluminum Nitride (ALN) Ceramics

✅ Superior Thermal Conductivity – Efficient heat dissipation for high-power applications

✅ High Electrical Insulation – Ideal for semiconductor components

✅ Exceptional Thermal Shock Resistance – Reliable in extreme conditions

✅ Compatible Thermal Expansion – Matches well with Silicon wafers

✅ Corrosion Resistance to Fluorine-Based Gasses – Ideal for harsh environments

✅ Outstanding Plasma Resistance – Suitable for semiconductor and aerospace applications

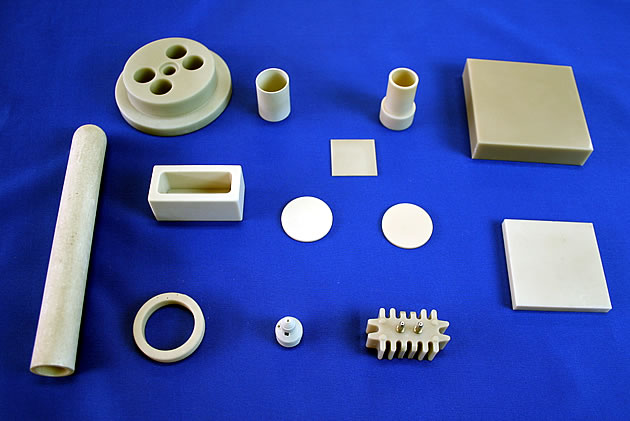

Available Shapes & Sizes

-

Nishimura Advanced Ceramics offers ALN products in various customizable shapes and dimensions, including:

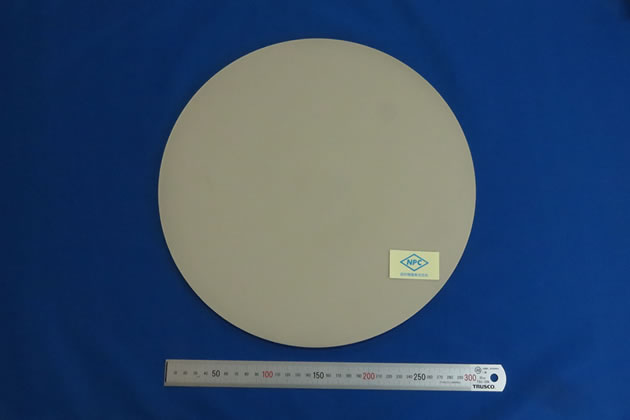

🔸 Plates, Bars, Pipes, Crucibles, Complex Designs – Fully adaptable for specific needs

🔹 Large formats available – Up to ∮600mm for demanding applications

🏭 Manufacturing Process

We employ cutting-edge ceramic engineering techniques:

- Machine Pressing – High-precision shaping

- Cold Isostatic Pressing (CIP) – Uniform density control

- Green Processing (Raw Material Machining) – Optimized for complex geometries

🔬 Applications & Industries

Our ALN ceramics are trusted in high-performance electronic and industrial sectors, including:

✔ Heat Sinks & Baseboards – Efficient heat management in electronic circuits. heat dissipation substrate for LD(Laser Diode), power semiconductors and optical communication lasers in the 5G era.

✔ Semiconductor Device Parts – Integrated into advanced fabrication processes

✔ Soaking Plates for Heaters – Enhancing thermal stability

✔ Crucibles for OLED Manufacturing – Essential for high-purity production

✔ Aerospace Industry Components – High-reliability thermal protection

✔ Semiconductor Device Parts – Integrated into advanced fabrication processes

🔹 Want to optimize your thermal management with ALN ceramics? Contact us today!

| AlN material | Nishimura No. | |||

| Properties | AlN-170 | AlN-250 | AlN-HYO | |

| Thermal conductivity | W/mk(R・T) | 170 | 250 | 90 |

| Thermal emissivity | (100℃) | 0.93 | 0.93 | 0.93 |

| Thermal expansion coefficient | 10⁻⁶/℃(RT~400℃) | 4.5 | 4.5 | 4.5 |

| insulation resistane | Ω・cm(RT) | >10¹³ | >10¹³ | >10¹³ |

| Dielectric strength | kV/mm(RT) | 15 | 15 | 15 |

| Dielectric constant | (1MHz) | 8.8 | 8.8 | 8.8 |

| Dielectric loss | 10⁻⁴(1MHZ) | 5 | 5 | 5 |

| Fracture toughness | kgf/mm² | 35 | 40 | 40 |

| Bulk density | g/cm³ | 3.32 | 3.32 | 3.23 |

| Y | % | 3.5 | 3.3 | 0 |

| O | % | 1.5 | 1.2 | 0.58 |

| Metal inpurity | ppm | <500 | <500 | <500 |

| Feature | Standard use |

High thermal conductivity | High purity | |