Porous Ceramics and Sealing Process for Semiconductor Gas Filters

In producing porous ceramics used in semiconductor gas filters, only the sides of porous rods with pore diameters in the micrometer (μm) range are sealed with dense alumina layer.

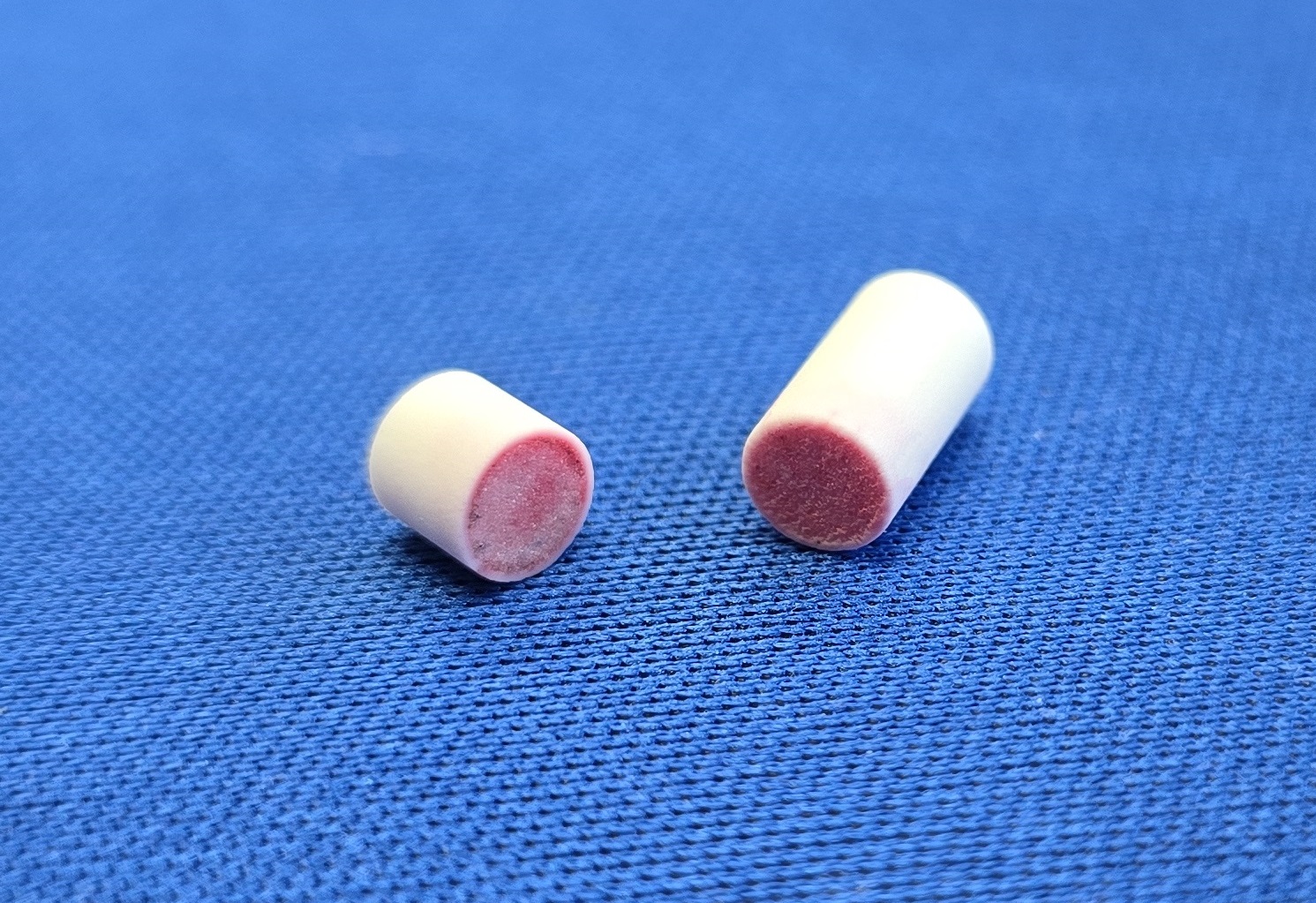

As a performance test, we applied a color agent to the sealed porous rods. The color agent penetrated the edge surfaces but did not seep through to the sides, demonstrating the effectiveness of the alumina sealant.

Applications:

- Gas filters (Implementation results: Semiconductor industry)

- Other filtration systems require precise pore size control

- Use a Thermal Insulating Materials: Porous ceramics are also used as insulating materials. Sealing the outer periphery improves thermal insulation performance, preventing heat loss and allowing the ceramic to be used more effectively as an insulating material.

- Performance Enhancement for Biomedical Applications: In the biomedical field, for instance, sealed porous ceramics are used as precise filters and controlled-release systems for drugs. Sealing the outer periphery prevents drug leakage, ensuring efficient delivery to the target site.

- Pollution Prevention and Purification

In environmental applications, filters made from porous ceramics are used for air and water purification. Sealing the outer periphery improves filter efficiency, enabling more effective removal of pollutants.

Key Points:

- Improved Efficiency of Gas and Liquid Filters: Sealing the pores on the outer periphery allows for controlled flow paths within the ceramic filter, enhancing filtration efficiency. Preventing leaks from the outer edges ensures that the flow follows specific paths, thereby improving the filter’s performance.

- Sealing Process: Dense alumina seals the sides of the rods, ensuring no leakage through the sides.

- Testing: Demonstrated that only edge surfaces absorb the color agent, confirming the integrity of the side seals.

- Enhanced Precision in Semiconductor Manufacturing Processes: In semiconductor manufacturing, extremely high-purity gases and liquids are required. Sealing the outer periphery prevents the contamination of these substances, thereby improving the stability and precision of the manufacturing processes.

- Increased Durability and Longevity: By sealing the outer periphery, the ceramic becomes more resistant to degradation, enhancing its durability. This reduces the frequency of maintenance and replacement, leading to cost savings.

- Improved Chemical Stability: Sealing the outer periphery enhances the ceramic’s resistance to chemical attacks from external sources. This makes the ceramic suitable for use in harsh chemical environments, broadening its applications.

Optimize your filtration systems with our advanced porous ceramics, which are perfect for semiconductor gas filters and more.