|

|

Wear-resistant engineering ceramics collection

Usage

– powder processing, mills, liner balls

– Wear-resistant liners for steelmaking and power generation.

– Wear-resistant precision surface plates and jigs.

– Mortars and pestles For physics and chemistry experiments

– Mortars for food grinding

– Wire rollers for wire erosion machines

Ceramics Pot for Planetary Ball Mill 99.7% Purity Alumina (Wear Resistant)

|

Wear Resistant Ceramics Pot for planetary ball mill with 99.7% Purity Alumina Details |

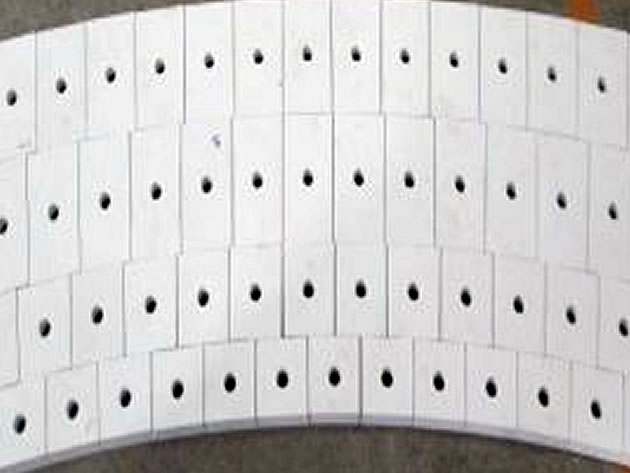

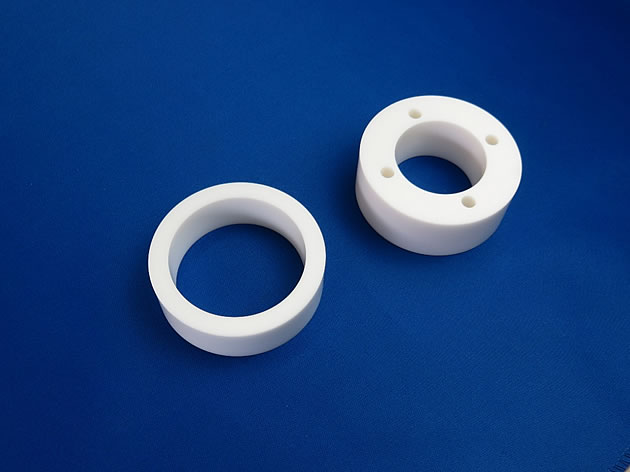

Wear resistance liner (Inner lining)

|

We deliver ceramic wear-resistant liner blocks with a proven track record of delivery and excellent QCD. Details |

ZTA (Zirconia Toughened Alumina) Pipe

|

This material is made by adding zirconia, which has high wear resistance and fracture toughness, to alumina, which has high hardness and high thermal conductivity. The percentage of zirconia added can be adjusted by 15%, 30%, and a particular grade of 40% to meet your requirements. Details |

Silicon Nitride ball mill crushing ball

|

Feature:High fracture toughness Chemical resistance Wear resistance In the application of non-oxide ceramics pulverizing and glass frit pulverizing in the semiconductor field, our products have shown better performance in crushing effectiveness. Also, its wear resistance can reduce the mixing issues of Silicon Nitride.Community Verified icon Details |

Ceramic Surface Plate (hybrid type) (high-purity alumina) (JIS00)

|

High-purity alumina ceramic with high quality granite on top. Highly accuated and reached Grade JIS00 (Flatness 2.5um) Details |

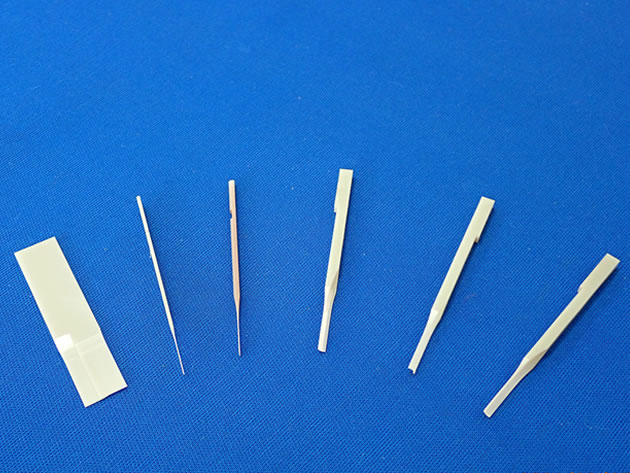

Lead frame copper stamping zirconia pin

|

At the copper material lead frame stamping line, Tungsten metal material is used as a stamping pin generally. Details |

Hollow set screw with Ceramics head (Hexagon socket set screw)

|

Hollow set screw with Zirconia Ceramics head/cap (Hexagon socket set screw). Assembled in Kyoto, Japan. Zirconia ceramics material has excellent wear resistance / Compressive strength. Details |

High purity Alumina Mortar and Pestle

|

A Mortar and Pestle using High purity Alumina 99.7% ceramics. Details |

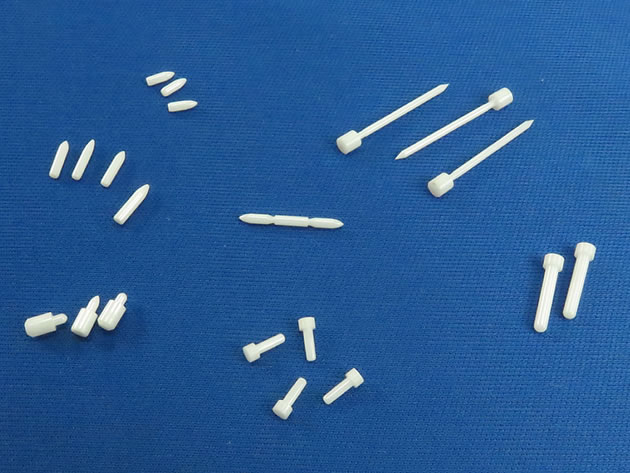

Positioning/Location/Guide pin Zirconia ceramics

|

Nishimura’s Zirconia pin is used for welding or chemical processing. Details |

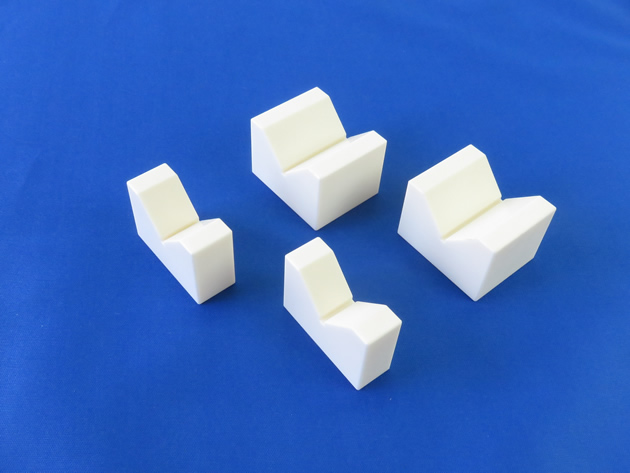

V-block Alumina ceramic jig

|

We produce V-block by Alumina (Al2O3) which is used as a jig Details |

Zirconia end mill

|

We have produced an endmill made of zirconia ceramics. It is made for processing graphite. Details |

Zirconia Ware proof parts(Machine/Robot parts)

|

Zirconia ware proof/resistant parts for EDM machine. Zirconia parts are used for machine/robot’s sliding parts a lot since Nishimura’s Zirconia has great ware proof. Details |

Ceramic mill stone

|

We produce mill stone by ceramic. We are using press molding for it. It is able to mass production. Details |

Ceramic stone mill for tea grinder

|

Alumina mill stone is used for consumer-electric makers’s tea grinder. Details |