Alumina Ceramics

Low dielectric loss tangent ceramics for high frequency

|

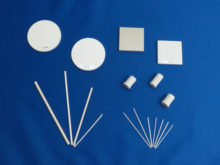

Features ・Low dielectric loss in GHz or MHz band. ・Several types are available. Low dielectric constant type(ε), low dielectric loss tangent type and strong type, etc. ・We can produce simple-shaped parts such as plates, but also small and complex-shaped parts. Moreover, we can supply it as filler.

More details are here |

N-99 Alumina purity 99% series

N-99A Alumina purity 99% White color ceramics

|

Features ・Alumina purity 99% |

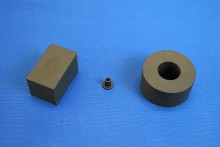

N-92D Alumina purity 92% Black color ceramics

N-9B Alumina purity 99% Black color ceramics