| thermal conductivity | dielectric constant | thermal expansion coefficient |

This page is the comparison of thermal expansion between other materials (Metal, Glass, or Quarts) and Nishimura’s ceramic.

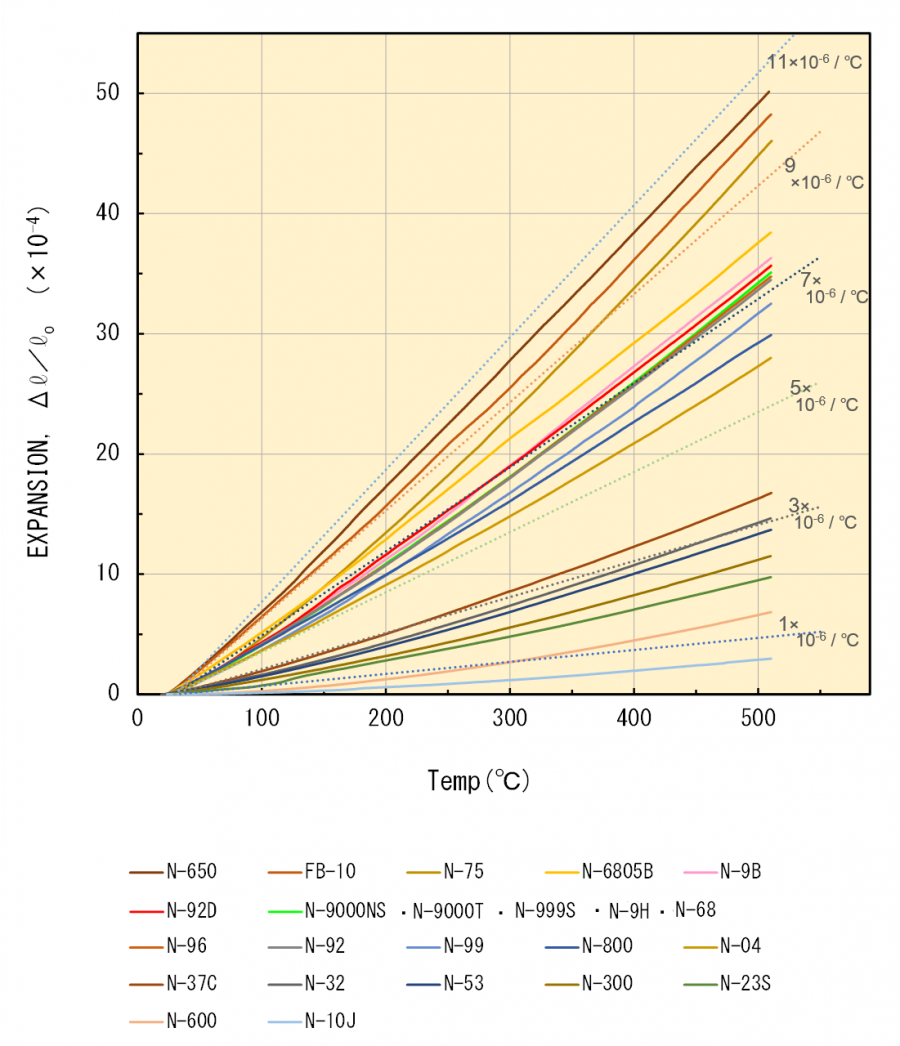

Compare Nishimura ceramics by thermal expansion coefficient.

Please use this page for finding a compatible ceramics or an alternative material.

| Material Name | Nishimura No. | Thermal expansion coefficient (CTE)(×10-6/℃)※1 |

Comparison between other material※2 | |||

| 30℃~100℃ | 30℃~200℃ | 30℃~300℃ | Metal | Glass or others | ||

| – | – | – | – | – | Over 20×10-6/℃ :Aluminum 10~20×10-6/℃ :Silver, Cupper, Gold, SUS304, Nickel |

Over 40×10-6/℃ : Epoxy, Acrylic, Phenolic resin, or others. |

| Zirconia | N-650 | 9.13 | 9.89 | 10.10 | SUS403 | |

| Forsterite(Black) | FB-10 | 8.40 | 9.10 | 9.50 | Platinum | |

| Forsterite | N-75 | 8.31 | 8.70 | 8.97 | Titanium | B270 Glass |

| Steatite(Black) | N-6805B | 6.81 | 7.35 | 7.75 | Inconel | BK7 Glass |

| Alumina (Black) | N-92D | 5.81 | 6.67 | 6.93 | ZnSe | |

| Alumina (Black) | N-9B | 5.79 | 6.48 | 6.98 | ||

| Steatite | N-68 | 6.08 | 6.47 | 6.73 | ||

| Alumina | N-9000NS | 5.53 | 6.27 | 6.62 | ||

| Alumina | N-9000T | 5.69 | 6.29 | 6.72 | ||

| Alumina | N-9H | 5.43 | 6.30 | 6.72 | ||

| Alumina | N-99 | 4.99 | 5.71 | 6.14 | Germanium | |

| Alumina | N-999S | 5.55 | 6.34 | 6.69 | ||

| Alumina | N-96 | 5.61 | 6.18 | 6.59 | ||

| Alumina | N-92 | 5.63 | 6.18 | 6.48 | ||

| Standard Porcelain | N-04 | 4.81 | 5.20 | 5.39 | Molybdenum | SiC(Silicon Carbde) |

| Mullite | N-800 | 5.40 | 5.67 | 5.84 | Kovar | Graphite |

| Zircon | N-37C | 2.57 | 2.88 | 3.13 | Pyrex Glass(Borosilicate glass), Gallium Nitride(GaN) |

|

| Zircon Cordierite | N-32 | 2.08 | 2.42 | 2.67 | Tungsten | Silicon(Si) |

| Cordierite | N-53 | 1.92 | 2.25 | 2.48 | ||

| Zircon | N-300 | 1.61 | 1.83 | 2.03 | ||

| Cordierite | N-23S | 0.97 | 1.62 | 1.76 | Diamond, Boron Nitride(Bn) |

|

| Dense cordierite | N-600 | 0.36 | 0.73 | 0.98 | ||

| β-spodumene | N-10J | 0.20 | 0.54 | 0.44 | Quartz | |

※1 This data is measured at the Kyoto Industrial Technology Research Center. The value on the data is representative value, not the guarantee value.

※2 The data of “Other materials” are reference value.

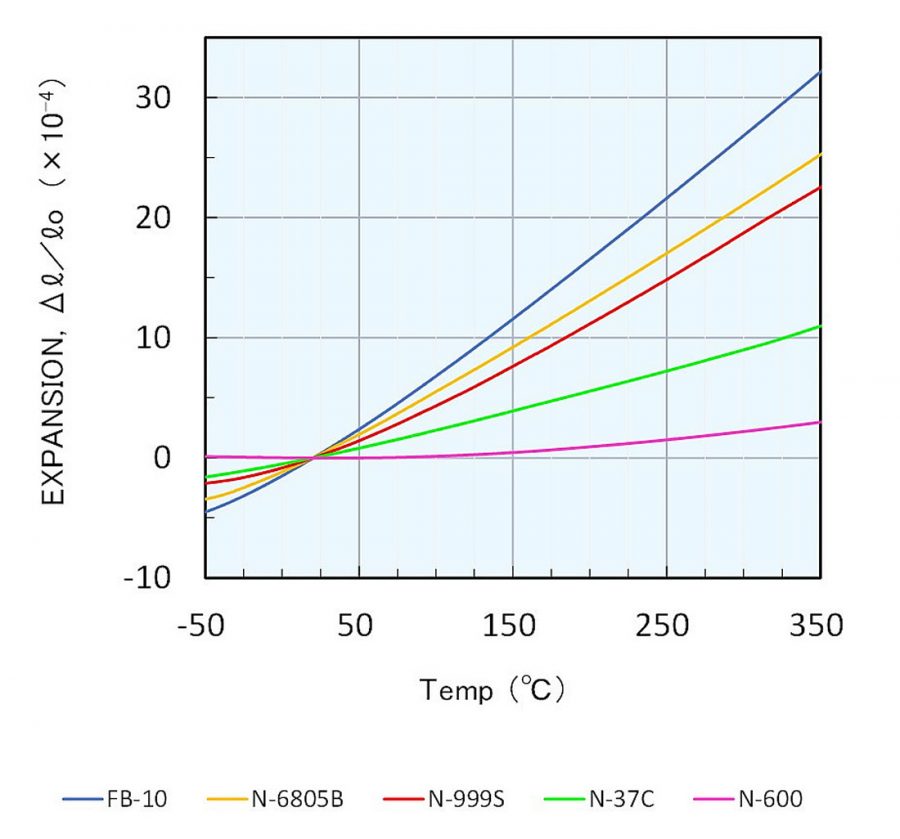

Liner thermal expansion coefficient of NAC Ceramics from Low temperature(Under 0℃)~Room Temperature~High temperature

- The table below shows the linear thermal expansion coefficient (CTE) of NAC’s ceramics in the temperature range of -50 ℃ to 350 ℃, and the graph of linear thermal expansion coefficient vs. temperature. The data shown are representative values and not guaranteed values.

- After decreasing the temperature from room temperature to -60 ° C at 5 ° C / min, the dimensional change was measured at a heating rate of 10 ° C / min. The measurement was conducted at a governmental public organization in the Kanto area.

| Material | NAC NO. | linear thermal expansion coefficient(CTE)(×10-6/℃)※1 | ||||||||

| -50~0℃ | 0~50℃ | -50~50℃ | -30~70℃ | 0~30℃ | 20~30℃ | 20~100℃ | 20~200℃ | 20~300℃ | ||

| Forsterite(Black) | FB-10 | 6.05 | 7.75 | 6.90 | 7.54 | 7.50 | 7.62 | 8.51 | 9.20 | 9.58 |

| Steatite(Black) | N-6805B | 4.58 | 6.25 | 5.42 | 6.11 | 6.05 | 6.46 | 6.91 | 7.27 | 7.53 |

| Alumina 99.9% | N-999S | 2.61 | 4.51 | 3.56 | 4.32 | 4.26 | 4.50 | 5.43 | 8.98 | 6.69 |

| Zircon | N-37C | 2.21 | 2.63 | 2.42 | 2.61 | 2.56 | 2.62 | 2.89 | 3.09 | 3.21 |

| Low CTE cordierite | N-600 | -0.19 | -0.04 | -0.12 | -0.04 | -0.09 | -0.05 | 0.17 | 0.52 | 0.78 |